Case Studies

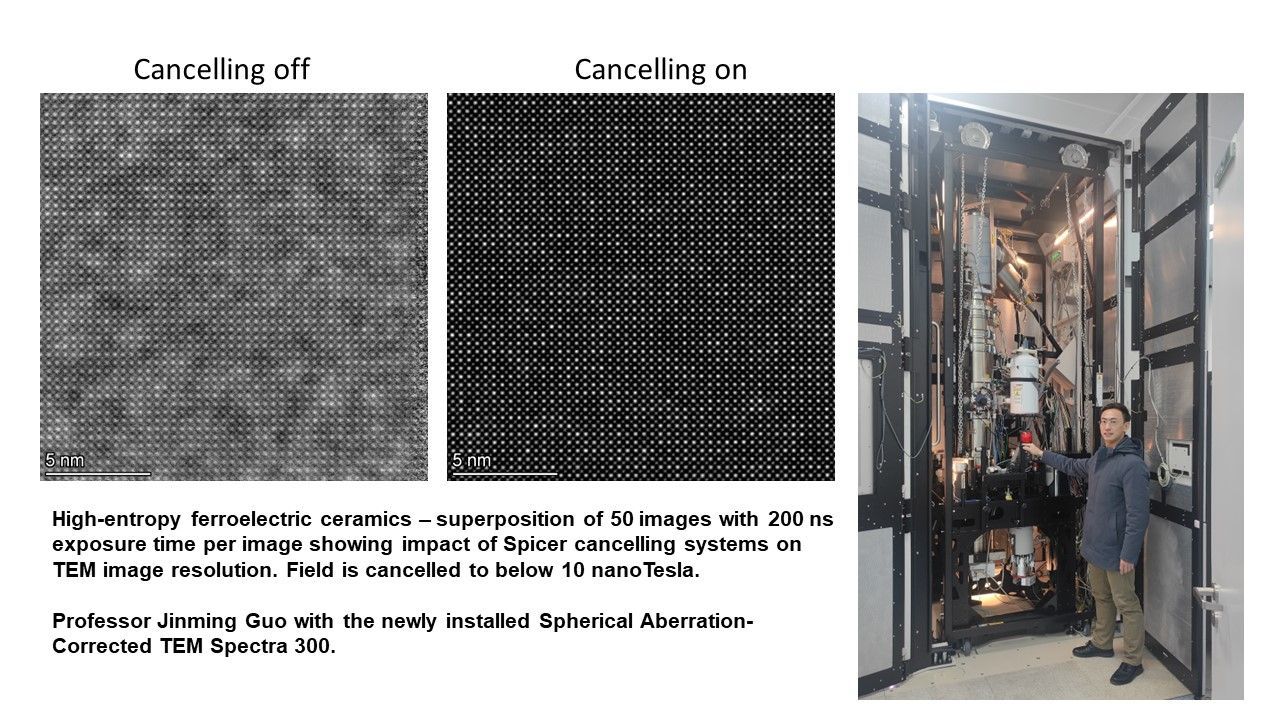

The performance of an electron microscope operating at high levels of magnification can be affected by a whole host of external factors – such as vibrations and temperature variations – limiting the quality and resolution of the images generated. Magnetic field interference can be especially problematic, and equally challenging to rectify, often requiring the instrument to be placed in ‘quiet’ locations that do not best serve the lab workflow. Fortunately, dedicated magnetic field cancelling systems can be employed to actively eliminate external fields, allowing microscopes to perform to their specifications, producing high resolution images even in challenging locations. In this case study, Jinming Guo, Professor of Materials Science and Engineering at Hubei University in China, describes how a Spicer Consulting SC24 Magnetic Field Cancelling System is assisting in the study of ferroelectric materials at an atomic level.

Magnetic fields are everywhere, radiating from such diverse sources as power networks, electrical equipment and even the earth’s core. For the most part, they do not interfere with everyday activities, but state-of-the art technologies operating at extreme levels of precision can be susceptible to even the most minute disturbances. For example, the image resolution of scanning electron microscopes (SEMs) can be negatively affected by magnetic field interference, preventing the equipment from being used to its full potential. Fortunately, magnetic field cancelling systems can attenuate such disturbances, and the University of Granada in Spain has recently installed an SC24 Magnetic Field Cancelling System to enhance the performance of its SEM set-up. Electron microscopes are used across a wide range of scientific disciplines, imaging everything from the inner workings of human cells to the complex crystalline structures of engineering materials, making access to state-of-the-art microscopy equipment essential for both academic and private researchers. Rocío Márquez Crespo, a technician at the University of Granada's Scientific Instrumentation Centre, explained: “I’m responsible for the Scanning Electron Microscopy Unit – located in the Faculty of Pharmacy – which provides services to research groups both here at the university and to other academic centres across Spain, as well as for many public institutions and private companies. As you can imagine, the applications we support are incredibly diverse, but the common thread running between them is the requirement for extremely high resolution images, and we accomplish this by providing access to both field emission and dual beam SEMs.” SEMs are well-known for their ability to measure features at the atomic level, but their precision and repeatability are heavily dependent on their surroundings, with factors such as vibration, temperature and humidity all affecting image quality. They are especially susceptible to external magnetic fields, since the images are generated using a beam of charged particles, which can be easily deflected by magnetic field disturbances. Rocío continued: “During the installation of our dual beam microscope, we noticed that images at the highest magnification settings were becoming distorted, and we suspected that it was due to magnetic field interference. An environmental survey carried out by the microscope manufacturer confirmed this to be true, and we were encouraged to purchase a magnetic field cancelling system to negate these effects. We’ve been recommended Spicer Consulting products many times in the past by colleagues and local researchers who’ve had positive experiences with them, so the SC24 Magnetic Field Cancelling System was the obvious choice.” The SC24 system comprises a magnetic field control unit, up to two magnetic field sensors, and three orthogonal axis multicore cables installed in the room where field cancellation is required. It stabilises the ambient field by dynamically creating nearly equal and opposite field changes, improving microscope performance. “Once the system was installed by Eloïse SAS – a local supplier – the high magnification image distortion disappeared at the flick of a switch. It was that simple,” Rocío concluded. Contact us f or more S C24 information. About Spicer Consulting Limited Spicer Consulting magnetic field cancelling systems protect electron beam instruments, including SEMs, transmission electron microscopes, electron beam lithography tools and SEM-based metrology and inspection tools. They are located in some of the world's leading laboratories, universities, semiconductor manufacturing plants and test facilities of electron and ion beam equipment manufacturers. The company’s magnetic field, vibration and acoustic analysis systems have also been adopted as the standard for conducting site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s golden triangle of elite universities in London, Cambridge and Oxford. About Eloïse SAS Eloïse SAS is a leading French scientific equipment company with 20 years of expertise in distributing and servicing electron microscopes and accessories. It offers the full Ted Pella/Pelco portfolio to French speaking countries, along with: vibrational & magnetic active compensation solutions (Spicer Consulting with K&S advanced); metallization and carbon evaporation equipment for sample preparation (Cressington); CCD-CMOS cameras for both on side and on axis TEM (Emsis); and nm resolution µ-electronic diffraction units for TEM, featuring 4D STEM with precession (NanoMEGAS). For more information, demos and training, visit Eloïse SAS at its Tremblay CDG AppLab, or explore the website at www.eloise-sarl.fr .

Today’s transmission electron microscopes (TEMs) offer high resolution and magnification capabilities but, to maximise an instrument’s performance, external interferences – such as vibrations arising from sounds or motion and magnetic fields created by other electronic equipment – must be eliminated. Researchers at Cataler Corporation have turned to Spicer Consulting to help them to optimise their equipment for investigations into non-homogeneous catalysts. Cataler Corporation specialises in the development and manufacture of catalysts and activated carbon products for the automotive industry. Masanao Sato worked for several years building up expertise in TEM technology, and is now applying his knowledge as an engineer in the analytical electron microscopy (TEM/SEM) department at the company. The department is working on the development and analysis of catalysts for exhaust purification, as well as materials for next generation vehicle batteries. Masanao described the work carried out by his group, and how they rely on accurate TEM imaging: “The catalysts we are investigating are non-homogeneous, and their performance is often affected by their ultra-fine structures. It is very important to perform structural analysis using high-end TEM during the research phase, so that the results can be fed into the development plans for new products.” “It was important for our work that we maximised the performance of our TEM by removing any interferences, including external vibrations and stray magnetic fields from other electronic devices in the vicinity. We therefore installed the TEM in a seismic isolation structure that has an independent base, to guard against vibration, whether from nearby traffic or elevators. We then conducted an environmental survey, and decided to purchase the Spicer Consulting SC24 magnetic field cancelling system as a countermeasure to prevent the effects of external magnetic fields.” The SC24 magnetic field cancelling system detects external magnetic fields with built-in sensors, and creates a new magnetic field, in an opposite direction, so that the two fields cancel each other out. Masanao is very satisfied with the system’s performance and how easy it was to integrate and use: “The SC24 had been in continuous operation since the TEM was installed and it still runs faultlessly. Since it is so compact, it was very easy for us to find space for it in our lab, and we could start using it straight away. Another thing that I really like about the instrument is how easy it is to operate; you do not need any knowledge about it in advance to start using it.” About Spicer Consulting Spicer Consulting magnetic field cancelling systems protect electron beam instruments, including Scanning Electron Microscopes (SEM), Transmission Electron Microscopes (TEM), Electron Beam Lithography tools, SEM-based metrology and inspection tools in the world's leading laboratories, universities, semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford. Technolab Inc. is Spicer Consulting Limited’s distributor in Japan. They provide technical and sales support for Spicer’s products. Visit http://www.technolab.jp/ for more details.

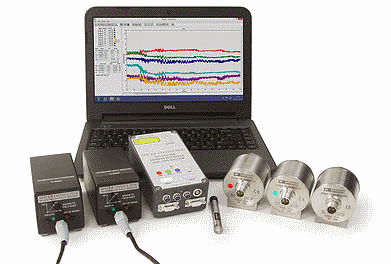

Electron beam lithography is commonly used to fabricate small devices used in computers, photonics and sensors. Since the technology relies on accurate positioning of the electron beam, it is very sensitive to interferences like vibrations and stray electromagnetic fields. Elliot Cheng, Electron Beam Lithography (EBL) Specialist, and Roger Wepf, Director of the Centre for Microscopy and Microanalysis (CMM) at The University of Queensland, describe how they solved this problem using a Spicer SC24 magnetic field cancelling system. CMM is an electron microscopy facility involved in research and teaching, as well as providing consultancy services. The centre offers expertise in different electron microscopy technologies and has recently built a new clean room where computer, photonics and sensor devices are fabricated using EBL. However, the new facility immediately began to present real challenges to the researchers when they started seeing unexplained background noise showing up in their data. Elliot explained: ”The devices we’re making are extremely small and it is crucial that the electron beam is accurately positioned, something that is greatly affected by any magnetic interferences. Ideally, levels on this kind of application should not be higher than 0.5 milligauss, but we were seeing peaks located around 50 Hz that were significantly higher than that, which jeopardised the accuracy of the instrument.” “We used the Spicer SC11 analysis system to scan for factors that might cause this interference around the lab, and it was extremely convenient to have a portable sensing system that allowed us to chase down the sources of noise without having to call in an external contractor. We started by investigating the vibrations, which we quickly realised were not causing the problem and moved on to checking the AC magnetic fields, looking at the contributions from various frequencies. When that proved fruitless, we analysed the DC fields and found that this was the root of the issue. This led us on a ‘ghost hunt’; we walked around with the SC11, turning different instruments on and off, moving the elevators, all while constantly measuring the changes in the field. After a while, we could attribute some of the spikes to the elevators, which was not surprising, but another source remained unknown. It was periodic, with a one-minute cycle and eventually we figured out that it was caused by the inductive heating of the lab.” “We had the answer but it didn’t really help us solve the issue. We couldn’t remove this source of interference, and started to schedule our runs during hours when no one else was in the building, which was between 11pm and 4am. Some of the processes were automated and we could get around this by programming them in advance, but this really limited the usability of the instrument. We therefore decided to purchase the Spicer SC24 magnetic field cancelling system, and immediately noticed a great improvement in the noise reduction – going from around 2 to just a few tenths of a milligauss – and we no longer have to worry about moving elevators or the nearby traffic. We still need to optimise the location of the sensors to get the best performance out of them, but the instrument is already doing a great job now that the problem of interference has been mostly eradicated.” Roger continued: “I have worked with Spicer for a long time; I started using their products around 1996 and have always used its instruments to perform an environmental survey every time we have installed a new instrument. I believe that it is absolutely essential to have a Spicer analysis system in every EM lab, because it saves a lot of time, and gives the team the freedom to perform on-site measurements as soon as they are needed, or if changes to the environment occur.” About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford. Resonate Systems is Spicer Consulting Limited’s distributor in Australasia. They provide technical and sales support for Spicer’s products. Visit www.resonatesystems.com.au for more details.

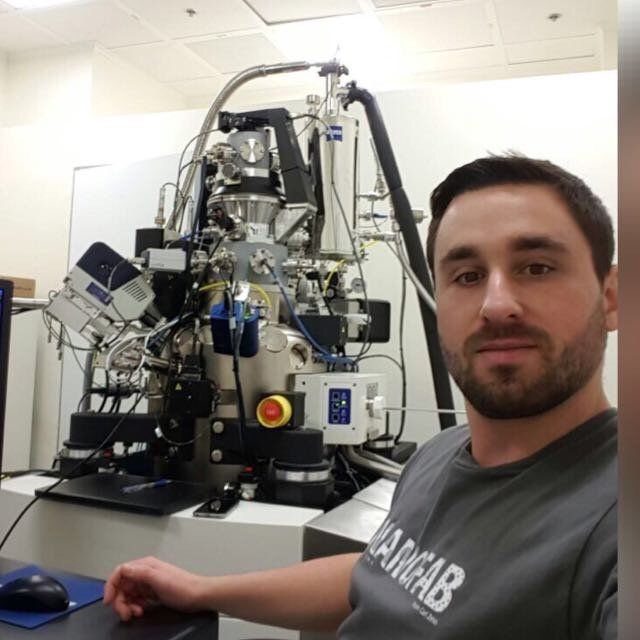

Transmission (TEM) and scanning electron microscopes (SEM), as well as focus ion beam (FIB) instruments are sensitive to interference from the environment, often arising from magnetic fields or vibrations. Active Solution Company Ltd. provides Spicer Consulting’s magnetic field cancelling systems to companies working with electron microscopes in the Korean semiconductor industry – for TEM, SEM and FIB platforms – to overcome the problems associated with interference. Advancements in semiconductor manufacturing have made production of tiny components on a nanometre scale more practical than ever before. Electron microscopy – such as TEM, SEM and FIB-SEM – is a vital quality control tool in the manufacture of these semiconductors, used to structurally analyse devices for any problems. However, image quality is commonly affected by external factors, and can make it challenging to identify faults. Jong Hwa Hur, President of Active Solution Company Ltd., explained: “When a customer experiences technical issues with their electron microscope, I visit their site and conduct a survey to measure and analyse for any interference and vibrations. This allows me to identify the causes and propose effective solutions. We supply Spicer Consulting’s magnetic field cancelling systems and active vibration isolation tables to help the semiconductor industry across Korea overcome electron microscopy problems.” “Magnetic field interference is normally caused by a 60 Hz frequency, commonly present from the abundance of different machinery in these manufacturing facilities. Additionally, the newest semi-conductor factories often feature monorail systems that have been installed in the ceilings to transport components such as silicon wafers between stations for automatic loading and processing. These systems are frequently overlooked, but can cause image interference if they are located too close to microscopy rooms.” Jong, who has been in the semiconductor industry since 1985, concluded: “I came across Spicer when I was first looking for a solution to magnetic field interference. Spicer is highly reputable and its magnetic field cancelling systems – the SC22, SC24 and SC26 – are very intuitive to use, requiring minimal training which can easily be conducted over email. My relationship with the company has developed ever since, and all of my customers are extremely satisfied with the Spicer products and how well they resolve image distortion issues. The additional features such as the real-time monitoring and auto-reset functions also make these systems excellent.” For more information on Spicer’s magnetic field cancelling systems, visit https://www.spicerconsulting.com/products . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

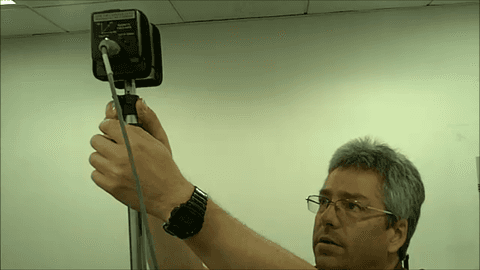

Electron microscopes are sensitive to magnetic and acoustic fields in the environment, and determining the cause of, and tackling, interference is vital to ensuring optimal performance. Global company Hitachi High-Technologies is using sophisticated surveying and cancelling systems to overcome the challenges faced when installing and maintaining this equipment. Hitachi High-Technologies is an international corporation that offers a wide range of cutting-edge products and services in four areas: science and medical systems; electronic device systems; industrial systems; and advanced industrial products. As part of its scientific systems, the company manufactures a variety of electron microscopes suited to all applications, as Carl Hordines, Southeast District Service Manager in the US, explained: “Hitachi offers a range of scanning and transmission electron microscopes which range in size from desktop to more than 10 feet tall taking up multiple rooms. Installation of these complex instruments is not always straightforward; they can be affected by electromagnetic interference (EMI) – caused by factors from transformers to elevators and metal doors – acoustic interference – from things like heating, ventilating and air conditioning (HVAC) systems – and even vibration – traffic, nearby building works or even someone just walking down a corridor.” “As part of the installation process, we survey the site using the SC11 Analysis System from Spicer to identify anything that might affect the microscope’s performance and recommend any preventative measures – such as field cancellation systems or vibration isolation tables – that might be required. For example, I recently surveyed a site where a large crane was in use and it was evident at the outset that this was going to cause interference with the microscope being installed. I was able to use the SC11 to measure the DC field while the crane was moving, and this confirmed what I had anticipated. This type of information helps us to advise the customer, perhaps suggesting where an instrument might be better placed in relation to external factors, as well as powerlines, and water and gas sources.” Carl continued: “We had already used a Spicer magnetic field cancellation system to prevent interference on a number of projects, when we saw a demonstration of the SC11 Auto Survey System. It was evident from this that our survey equipment needed upgrading and we decided to purchase several for our installation teams. The SC11 is purpose-designed for surveying sites for electron microscopes and other sensitive equipment, and offers a higher quality microphone and more sophisticated sensors than our previous system. We no longer have to move the sensor numerous times to gather multiple readings, and the report generation is much quicker. I can use the macros to run a survey that gives us a really good snapshot of a location in around 25 minutes.” “The SC11 also increases the efficiency of data collection because the whole process is integrated into the system – it’s all automated. The software is compatible with Microsoft® Office so it’s easy to pull up data without the need to copy and paste between different programs. I have an Excel® spreadsheet for each model of microscope we offer, that will read raw data and populate the tables against the specifications for that particular instrument. This allows me to determine which models will work best in a specific space or facility, without the need for multiple site visits.” “For studies that are more complex, we can leave the system in place for extended periods of time. It is straightforward to schedule multiple runs or to start recording data when an interference hits a set level or, when the need arises, we ship a kit to a customer site if they unexpectedly encounter a problem. The system is very robust and comes with a durable shipping case, and it’s so easy to use that anybody can set it up with minimal instruction – even with no prior experience.” “The SC11 systems are now solely responsible for all of our internal and external surveying, which ensures continuity throughout our work, and we’re so happy with them that we have recently added two more to the four we already own; they are so efficient, we wouldn’t be without them,” concluded Carl. For more information on how Spicer can help you optimise your EM, contact us to find out here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

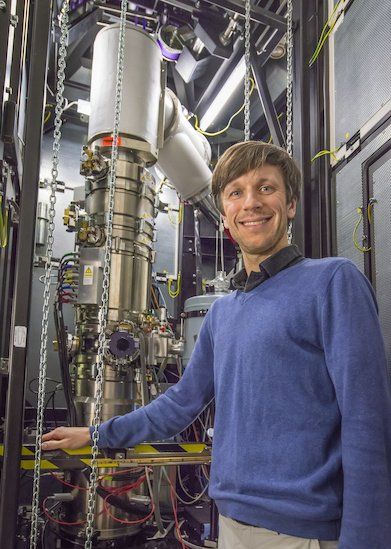

Electron microscopy is the method of choice in material science and biology research when high resolution imaging is required, however, environmental interference is a common problem that can affect image quality. Scientists at the Lawrence Berkeley National Laboratory (LBNL) are using a Spicer SC24 field cancelling system to help overcome these problems and enhance microscope performance. LBNL, based in the USA, is a national laboratory with a focus on bringing together multidisciplinary teams of researchers to advance scientific discovery. Within the laboratory is the National Centre for Electron Microscopy – a Molecular Foundry (MF) facility – that houses cutting-edge instrumentation for high resolution imaging and analytical characterization of a broad range of materials, which are available to researchers around the world. Peter Ercius, a MF staff scientist, explained this collaborative environment: “We have eight transmission electron microscopes – three of which are aberration corrected – and each has its own speciality. We offer everything from routine systems to the most advanced, atomic resolution 3D electron tomography. Researchers from any country are able to write a proposal and, if accepted, they are invited to come and use our facilities here, with the support of a team of experts on site.” Environmental interference limits the performance Electron microscopes are sensitive pieces of equipment that are susceptible to environmental interference from temperature fluctuations, mechanical vibrations and electromagnetic fields. These perturbations can shift the electron beam, lowering the image resolution and making it hard to get the most out of the instrument. Peter continued: “Although the newer systems are not as easily affected by interference, it still causes problems and affects the image quality, something that we experienced with one of our own microscopes. The images weren’t as good as I knew the system could produce – having used the same system during my undergraduate degree – objects that were round or should have had a sharp interface looked very jagged, so we knew the beam was unstable.” “It was apparent from the pattern of our interference that the frequency of the perturbation was 60 Hz, and most likely was being caused by power cables. However, the problem was often intermittent, and we didn’t know exactly where it was coming from, or how to fix the issue, suggesting that there were power surges occurring. The microscope was located at the end of the building, so was more susceptible to outside influences, and was also positioned near a door with a magnetic lock.” Looking to Spicer for a solution The facility already used a Spicer magnetic field cancelling system with one of its microscopes, and so the lab contacted Spicer Consulting’s USA distributor, Vibration Engineering Consultants (VEC), to discuss the new problem. Peter continued: “We also considered a number of other systems, but compared to Spicer they came up short and we decided to invest in a Spicer SC24, primarily because of its ability to cancel AC and DC magnetic fields. VEC helped with the installation and performed a site survey, uncovering that a chiller located near the microscope, and the opening and closing of the outside door were causing some of the interference we were experiencing, but we weren’t able to identify all of the sources.” “We considered placing all mechanical items on proper isolation padding, in combination with using the field cancelling system. However, installation of the SC24 proved to be a simple solution to a complex problem, significantly improving the image quality. The system is very intuitive, you just turn it on and, at the flick of a switch, the fields are cancelled in all three directions, allowing you to remove any interference. VEC supported us throughout the entire installation and, although there is a lot of expertise in our department, it was great to have additional backup and know-how during the process. We’re so happy that the issue has been overcome, and we are generating images of much higher quality,” concluded Peter. Spicer Consulting provides solutions to reduce magnetic field interference for higher resolution electron microscopy. Contact us to find out here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

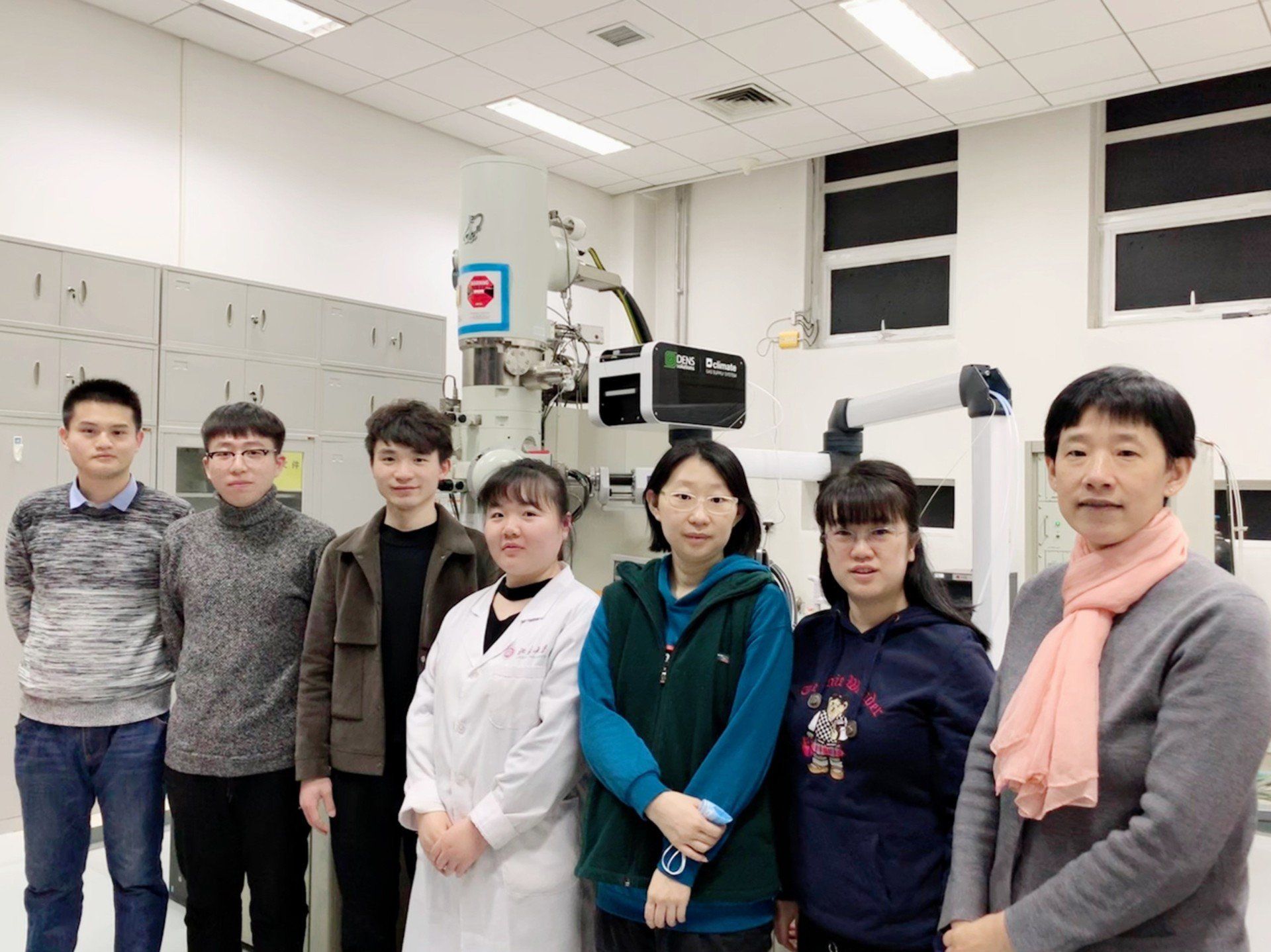

The quality of electron microscope images can be affected by interference from magnetic fields that are created by everyday equipment out of the researcher’s control, such as lifts and trains. Scientists are using field cancelling systems to escape this disturbance, increasing the performance of the instrument and, therefore, the resolution of images. Researchers at Peking University, China, have recently installed one of these set-ups to overcome the image distortion caused by external interference from magnetic fields. Electron microscopes are powerful, but sensitive tools used for obtaining high resolution images in many technical disciplines – from cell biology to materials science and engineering – and are integral to understanding the intricate structure of many biological and inorganic specimens. However, interference from surrounding magnetic fields generated by day-to-day electrical equipment can affect the resolution of electron microscopes, decreasing the quality of images obtained. Users of these sophisticated microscopes often turn to cancelling systems that drastically reduce both AC and DC magnetic fields to overcome these problems. Dr Jing Ju, a researcher in the College of Chemistry and Molecular Engineering at Peking University, China, explained: “My lab is the core facility for use of the scanning electron microscope (SEM), and we assist many departments and research groups with a range of projects, from studying bacteria and materials to the analysis of nanoparticle crystal structures. For SEM, we need a very high resolution image – typically a 200,000x magnification of the sample – with minimal interference.” Unwanted interference “Our laboratory is in a very old building and, unfortunately, there is a large electricity power cabinet emitting AC interference nearby, as well as a subway 100 metres away contributing to high levels of DC magnetic fields and acoustic noise from vibrations. This level of interference deflects the electron beam of the microscope, distorting the image. Our SEM system ideally needs to operate with an external magnetic field of less than one milligauss, but DC fields measured on the z-axis were 19 milligauss and AC fields on the x-axis were more than 21 milligauss. Both AC and DC magnetic fields were regularly out of range in our lab according to the SEM requirements, and so we explored using a cancelling system to stabilise the field by creating forces to oppose those from external factors.” Cancelling out the noise “We started using the SEM in around 2014, but it was only recently that we were introduced to different options for removing unwanted signals. After discussing with local advanced laboratory equipment supplier, Ke Chieh Tech, it was suggested that we tried one of Spicer Consulting’s systems, and the company performed a live demonstration of the cancelling equipment for us to see. We were so impressed with the efficiency of the instrument that, at the beginning of 2018, we purchased Spicer’s SC24 magnetic field cancelling system, and are amazed at the increase in quality of images we can produce. In fact, we can now reach a magnification of 300,000x, which is a huge improvement in resolution. The dynamic nature of the SC24 means that it detects and reacts to field changes within 100 microseconds, ensuring any interference is quickly cancelled out, which is very important in such a busy laboratory.” A trusted partnership “Our local supplier assisted in the installation of the SC24 system and we were taught how to maintain the equipment, which is very straightforward to do even for someone with minimal experience. Whenever we have needed support, the company has been readily available by phone or email to answer any questions and provide solutions to our problems, which have always been quick to fix. We are planning on moving the SEM to a new site soon, and will be using the company’s consultation service to assist in surveying the new environment, in order to detect any possible sources of interference and confirm whether it will be a suitable location. We are incredibly pleased with the performance of the cancelling system, and the support that we have received, and look forward to continuing to work with Spicer instruments in the future,” Jing concluded. Spicer Consulting provides solutions to reduce magnetic field interference for higher resolution electron microscopy. Contact us to find out here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Electron microscopes offer unparalleled image resolution and are widely used in research laboratories to investigate the structure of various biological and inorganic structures. These powerful tools are, however, susceptible to interference from magnetic and acoustic fields, which decrease the image quality. ZEISS, an internationally renowned optical expert, is therefore using sophisticated surveying equipment to inspect sites prior to system installation. ZEISS is one of the world’s leading manufacturers of optical systems and provides a wide range of services and products used for semiconductor production, research and quality technologies, medical devices and vision care. An example of this is the use of the company’s high resolution scanning electron microscopes (SEMs) for surface topology imaging in life sciences and materials research. The installation of such high tech equipment requires careful planning to ensure that they perform as well as the customers expect them to. Christian Hegele, International Service and Support Engineer at ZEISS, explained: “It is very important that the site is adequately surveyed before setting up an electron microscope; you need to ensure that the room is big enough, and check for interference that could decrease the image quality. Since electronic and acoustic interference, as well as floor vibrations, can have a huge impact on the performance of electron microscopes it is crucial to detect any problems that may arise in order to provide a solution.” Dedicated equipment to scan for interference ZEISS has been using the SC11 Sensor Interface Analysis System from Spicer Consulting since 2008, allowing the company to survey the environment and check if laboratories are suitable prior to installation. Christian continued: “The system is very user-friendly and the results are displayed graphically on connected laptop screens, allowing us to reliably assess the area. We have created templates specifying the requirements of each of our microscopes, which can simply be run on the SC11 system using the Spicer Wizard software; everything is automated, making it extremely easy to use, even for less experienced service engineers. The templates are available online and can be accessed by our staff around the world, and since the majority of our service engineers are now using Spicer equipment, it means that we can ensure consistently high quality results. It’s an excellent way to standardise the service that we provide, and allows us to have confidence that each survey will be performed with accuracy and reliability, and to ensure that our staff is familiar with the benefits of the systems.” Long collaboration with Spicer Spicer was recommended to Christian by one of his colleagues, a former service engineer who had years of experience with its magnetic field cancelling systems. Christian continued: “I went on a two-day course organised by the company before I started performing the surveys, where I learned more about the system as well as how to train our own engineers. This was a really interesting experience, and the products were fantastic. We are now working on establishing an in-house training programme for new engineers, or those switching over to the Spicer systems. On top of that, we also use Spicer’s purpose-designed SC22 Magnetic Field Cancelling Systems, which can reduce stray magnetic fields – both AC and DC – and also handles vibrations. The SC22 increases the resolution and accuracy of our SEMs and, when surveying our customers’ sites, we often recommend this tool to enhance the performance of our systems, as it is incredibly effective at removing interference.” “We work extremely closely with Spicer in order to deliver the best possible service to our customers. Both the SC11 and SC22 are intuitive and easy-to-use, and if we ever encountered any problems or simply wanted to make changes to the systems, our enquiries were quickly and efficiently addressed. We have an excellent relationship with the team after years of using their products, and are incredibly impressed with what they do. We work very well together and are looking forward to continuing our collaboration with Spicer in the future,” Christian concluded. Contact Spicer Consulting Ltd for our SC11 site survey kit or magnetic field cancelling system here . About Spicer Consulting Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focussed ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers.Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers.

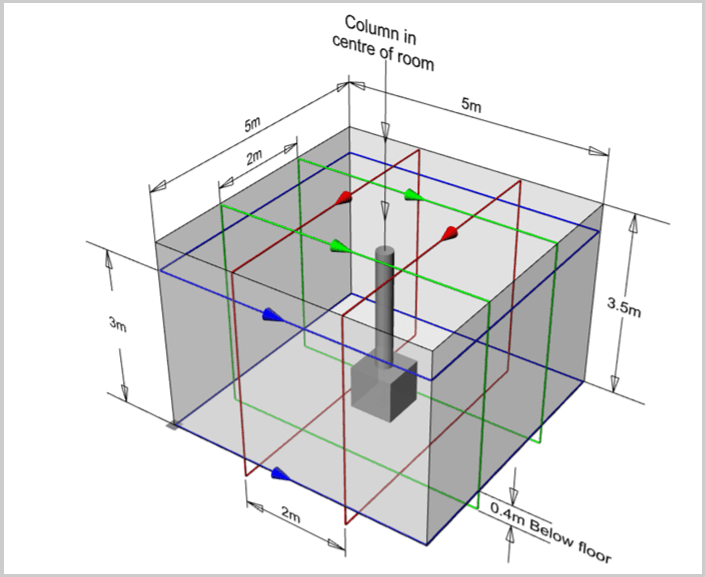

When the University of Cambridge Department of Biochemistry was looking to install a Thermo Fisher (former FEI) Titan Krios electron microscope, the location proved problematic due to a range of magnetic field interference. The team from Spicer Consulting also faced the challenge of not being able to run cables across the floor due to the Krios having a large dewar of liquid nitrogen that needs an unobstructed floor. The resulting solution is an SC24 Field Cancelling System with the Z-axis cable running around the room, whereas the X- and Y-axis cables are installed in the enclosure of the microscope itself. We asked Dr Dima Chirgadze, Cryo-EM Facility Manager what was causing the interference and why the Department had chosen Spicer Consulting:

We’re measuring the environment for some new microscopes at King’s College London. The microscope suite has five rooms. That could mean five to seven new microscopes being installed. To protect the investment in these, we want to make sure that the environment is good. As part of our Site Survey Service, we’re measuring magnetic fields, vibration and sounds levels to see if there are any issues.