Continuous environmental surveillance guarantees high-quality electron microscope imaging

Electron microscopes (EMs) are vital quality control (QC) tools in semiconductor production, helping manufacturers to guarantee a high standard of product. However, the precision of EMs and the resolution of resulting images can be hindered by external interruptions, such as acoustic noises, vibrations and magnetic fields. Low resolution and perturbed images can make it hard to detect faults in semiconductor products, which could in turn decrease the yield and performance of manufactured goods. Therefore, continually assessing the quality of the imaging environment and pinpointing any potential sources of disturbances is critical to maintaining a high standard of production. Fortunately, there are dedicated systems on the market designed especially for continuous monitoring of the environment surrounding sensitive EMs, which now provide uninterrupted and automatic logging of various environmental parameters to revolutionise electron beam (EB) instrument applications.

Failure analysis is an important component of QC in semiconductor production, which can ultimately help to enhance yield and guarantee a high standard of manufacturing excellence. However, smaller and smaller semiconductor devices are being developed, making it increasingly difficult to perform failure analysis and locate defects in products. Various high-resolution EM tools – including scanning electron microscopy (SEM), focused ion beam scanning electron microscopy (FIB-SEM) and transmission electron microscopy (TEM) – are helping to analyse the structure of even the smallest devices. This is crucial for localising and characterising defects and electrical problems that may affect performance, solidifying these EM instruments as cornerstones of the QC process.

Unfortunately, the environment in which the EM is located can have a significant impact on image quality, as external factors – such as acoustic noises, vibrations, and magnetic fields – lower the resolution and make it harder to find defects. In addition, these disturbances can also cause instability or shifts in the EB, resulting in significant reductions in resolution, so that instruments perform below their intended design specifications. It is therefore important to the quality of imaging that these types of disturbances are identified when the instrument is first installed within a semiconductor manufacturing or research environment. They must also be continually monitored throughout their use, as subsequent or transient changes to conditions can cause ongoing problems for operators.

Surveying the environment

Surveillance of the environment prior to installation should be a standard when investing in any EB instrument, in order to ensure that the microscope or lithography machine is placed in an appropriate location that will enable it to operate to its desired specifications. There are purpose-made survey systems for this application – such as Spicer Consulting's SC11 family – which are able to measure both vibrations and external magnetic fields. Once installed, many EB instrument users also perform long-term surveillance of the environment to help identify any drifts in continuous fields or transient disruptions that could impact performance. However, until recently, the technologies available for this ongoing environmental monitoring have been missing one critical feature – the ability to measure several parameters simultaneously without any interruptions in data collection.

Continuous feedback

An innovative monitoring system (SC28 Monitoring System, Spicer Consulting) that continuously logs magnetic fields and floor vibration in three axes, as well as acoustic levels, temperature and humidity, has recently launched onto the market. This system can be controlled via a computer connected to the same local area network, and all the gathered information is automatically stored in date-stamped files by the software. This program can also be used to define environmental specifications, either as minimum/maximum values, or as a spectrum of maximum amplitude versus frequency. The software constantly compares the measured values for each parameter with the user-defined specifications, and real-time results are displayed in a small window. The SC28 can be configured to send an email to the user if any parameters shift beyond the allowed margins. This can be done either once or at a specified frequency, making sure that the issue is dealt with in a timely manner. In addition, a traffic light beacon can be used to give a visual warning, something that can be useful in a manufacturing environment such as semiconductor production.

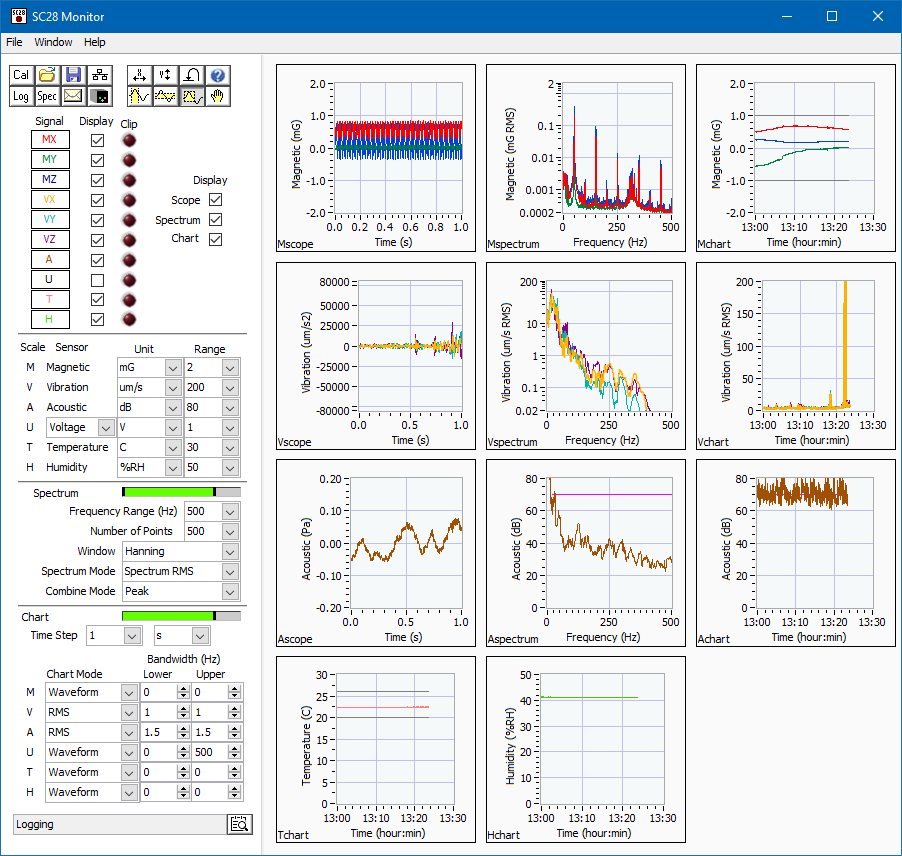

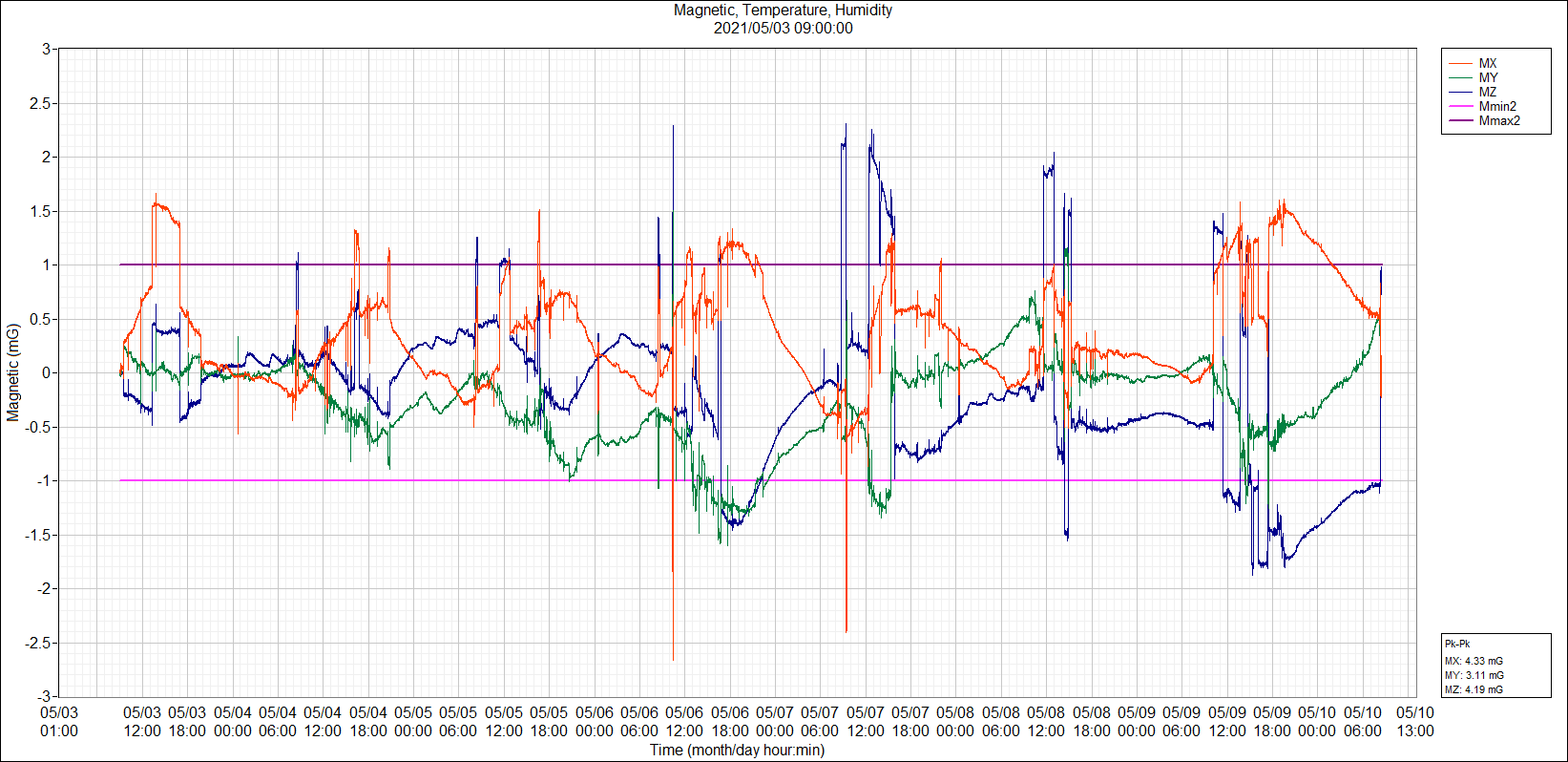

The program supports six scales and three different formats – scope, spectrum and chart – showing up to 14 graphs simultaneously (see Figure 1). A dedicated tool, SCplot, also allows users to handle large data sets and visualise changes in the environmental parameters over a long time period. For example, Figure 2 shows a week’s worth of magnetic field data extracted from nearly 70 Mbytes of data in 335 files, each containing 30 minutes of logging at one point per second of 3-axis magnetic field, 3-axis vibration, acoustics, temperature and humidity. The plots can be saved either as images or appended to a text file to simplify reporting. Furthermore, SCplot enables macro scripting, allowing the user to save command sequences and re-run them later.

A solution shared by EM manufacturers and users

EM tools are often used in applications that rely on precise, high quality images, such as advanced research or inspection and QC in the semiconductor industry, so it is important to protect them from environmental disturbances. Unfortunately, users of EM systems typically cannot identify external interference instantly, and it can take some time to determine the underlying cause of image distortion, delaying research or manufacturing activities. The SC28 monitoring system can provide 24/7 environmental monitoring for these tools, and help to quickly diagnose issues arising from external perturbations. It can also be used as an alarm system, constantly comparing the measured environmental readings to the microscope specifications or user-determined thresholds, allowing local visible warning and sending an error report if a parameter is out of specification. This provides EM operators with complete peace of mind about the long-term stability of their instrumentation.

The SC28 is not only useful for EM operators, but it can also be used by EM manufacturers to gather data about the instrument and upload it to the cloud so that a service engineer can analyse it remotely whenever there is an issue with the EM’s image resolution. This can allow the engineer to quickly determine whether the problems are related to the environment or to the instrument itself, ensuring that issues can be identified and corrected as soon as possible. The SC28 can also be used by EM manufacturers to monitor ambient conditions as the instruments are assembled, helping to diagnose and solve problems created by unexpected external disturbances.

Conclusion

QC activity relies on important performance data, and the introduction of a continuous environmental monitoring solution is a gamechanger that helps to ensure the operational standard of EM and lithography systems. The SC28 offers continuous monitoring of vibrations, magnetic fields, acoustic waves, temperature and humidity – without any need for user intervention – helping to identify potential resolution issues stemming from external interferences, whether continuous, intermittent or transient, and giving users more control over their processes and environment.

Contact us for further information about the SC28

About Spicer Consulting Limited

Spicer Consulting magnetic field cancelling systems protect electron beam instruments – including scanning electron microscopes (SEM), transmission electron microscopes (TEM), electron beam lithography tools and SEM-based metrology and inspection tools – in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for conducting site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s golden triangle of elite universities in London, Cambridge and Oxford.