Knowledge Base

Knowledge Base

05 May, 2023

The unparalleled magnification capabilities of electron microscopes (EMs) make them indispensable for applications requiring nanometre scale imaging. However, the sensitivity required to operate at such high magnification levels leaves them vulnerable to magnetic field perturbations, vibration and changes in temperature and humidity, all of which need to be kept to a minimum to ensure peak performance. Keeping track of such environmental factors is no mean feat, but dedicated continuous monitoring systems are now available to detect changes in instrument surroundings in real time, simplifying troubleshooting procedures and ensuring optimal device performance. Blurred lines The superior magnification offered by EMs stems from the use of electrons instead of light to probe a sample; the wavelength of these particles can be many orders of magnitude shorter than photons on the visible spectrum, enabling them to resolve much smaller features. The beam of electrons is focused on the specimen, and interacts with atoms in the sample to produce signals that contain information about surface topography and composition. Seeing details at such a small scale requires the beam to be perfectly positioned and focused, which can be compromised by external interferences from acoustic noise and vibrations, leading to blurred images. Additionally, since the electrons are charged particles, EM performance is also greatly affected by external magnetic fields. This leads to distinct artefacts appearing in the image; AC fields often show up as sharp jagged edges, while DC fields create wavy lines. EM manufacturers therefore precisely map and specify the degree of interference that their instruments can handle before the image quality drops below the acceptable limit.

05 May, 2023

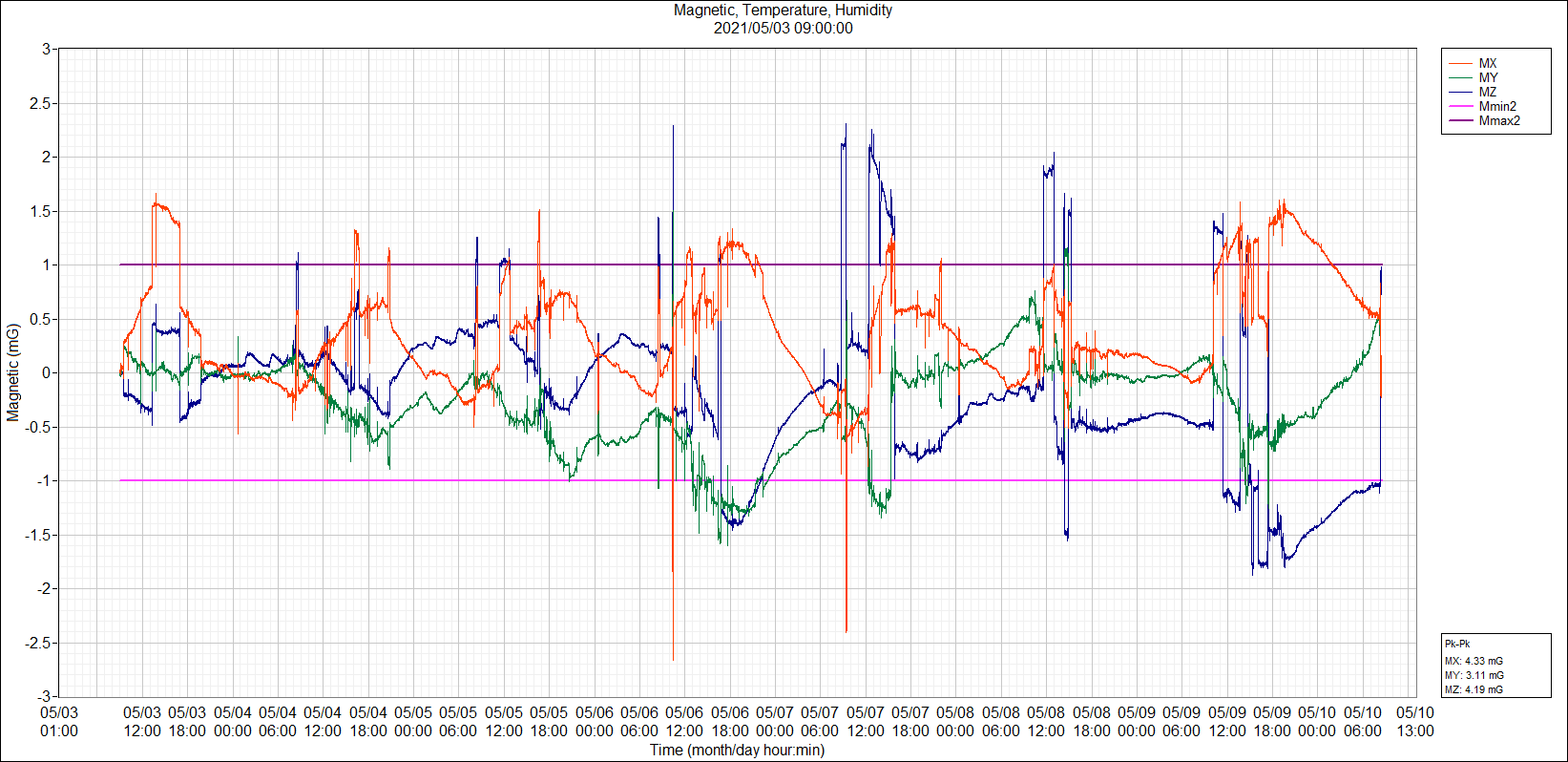

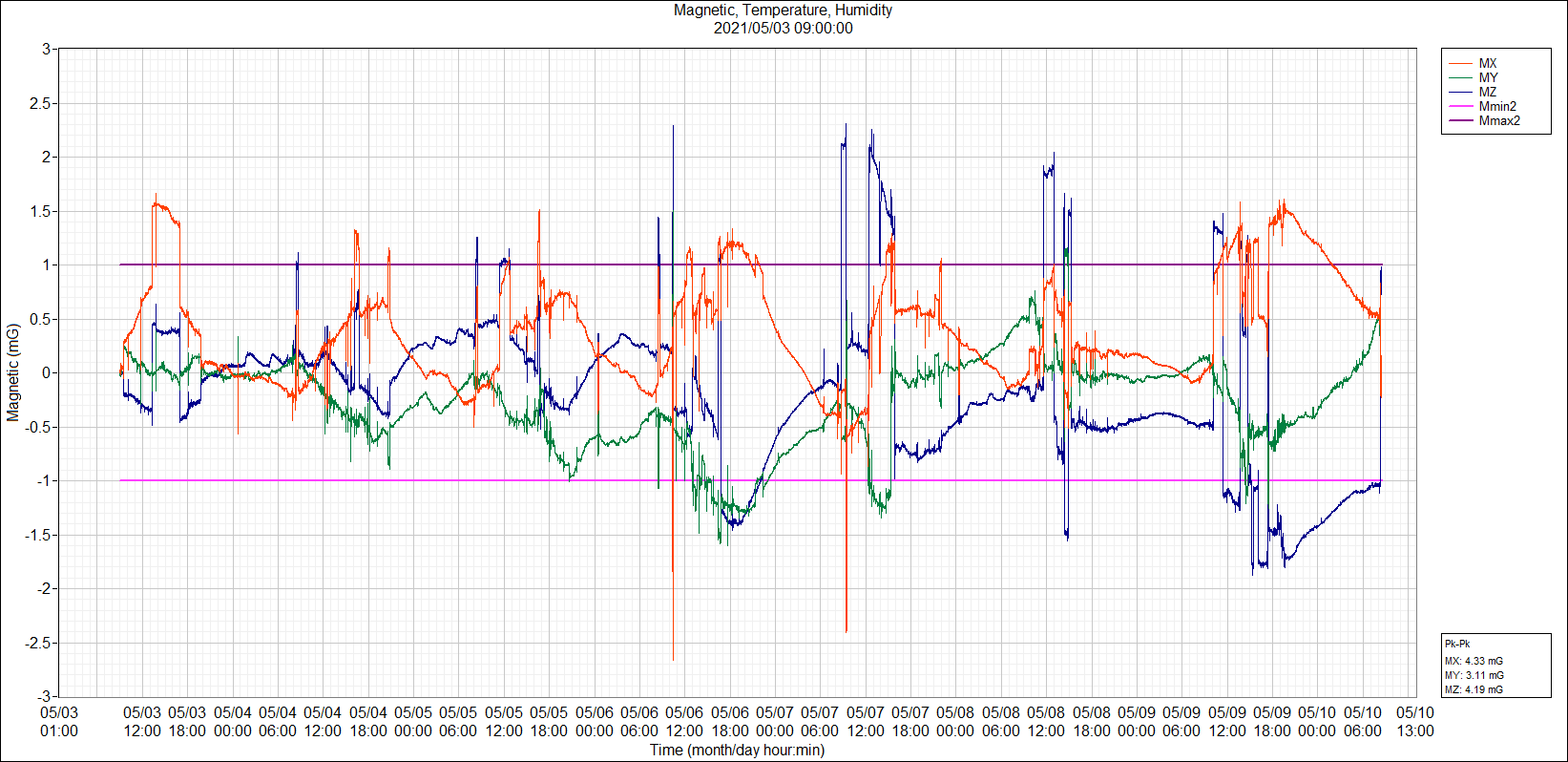

Electron microscopes (EMs) are vital quality control (QC) tools in semiconductor production, helping manufacturers to guarantee a high standard of product. However, the precision of EMs and the resolution of resulting images can be hindered by external interruptions, such as acoustic noises, vibrations and magnetic fields. Low resolution and perturbed images can make it hard to detect faults in semiconductor products, which could in turn decrease the yield and performance of manufactured goods. Therefore, continually assessing the quality of the imaging environment and pinpointing any potential sources of disturbances is critical to maintaining a high standard of production. Fortunately, there are dedicated systems on the market designed especially for continuous monitoring of the environment surrounding sensitive EMs, which now provide uninterrupted and automatic logging of various environmental parameters to revolutionise electron beam (EB) instrument applications. Failure analysis is an important component of QC in semiconductor production, which can ultimately help to enhance yield and guarantee a high standard of manufacturing excellence. However, smaller and smaller semiconductor devices are being developed, making it increasingly difficult to perform failure analysis and locate defects in products. Various high-resolution EM tools – including scanning electron microscopy (SEM), focused ion beam scanning electron microscopy (FIB-SEM) and transmission electron microscopy (TEM) – are helping to analyse the structure of even the smallest devices. This is crucial for localising and characterising defects and electrical problems that may affect performance, solidifying these EM instruments as cornerstones of the QC process. Unfortunately, the environment in which the EM is located can have a significant impact on image quality, as external factors – such as acoustic noises, vibrations, and magnetic fields – lower the resolution and make it harder to find defects. In addition, these disturbances can also cause instability or shifts in the EB, resulting in significant reductions in resolution, so that instruments perform below their intended design specifications. It is therefore important to the quality of imaging that these types of disturbances are identified when the instrument is first installed within a semiconductor manufacturing or research environment. They must also be continually monitored throughout their use, as subsequent or transient changes to conditions can cause ongoing problems for operators. Surveying the environment Surveillance of the environment prior to installation should be a standard when investing in any EB instrument, in order to ensure that the microscope or lithography machine is placed in an appropriate location that will enable it to operate to its desired specifications. There are purpose-made survey systems for this application – such as Spicer Consulting's SC11 family – which are able to measure both vibrations and external magnetic fields. Once installed, many EB instrument users also perform long-term surveillance of the environment to help identify any drifts in continuous fields or transient disruptions that could impact performance. However, until recently, the technologies available for this ongoing environmental monitoring have been missing one critical feature – the ability to measure several parameters simultaneously without any interruptions in data collection. Continuous feedback An innovative monitoring system (SC28 Monitoring System, Spicer Consulting) that continuously logs magnetic fields and floor vibration in three axes, as well as acoustic levels, temperature and humidity, has recently launched onto the market. This system can be controlled via a computer connected to the same local area network, and all the gathered information is automatically stored in date-stamped files by the software. This program can also be used to define environmental specifications, either as minimum/maximum values, or as a spectrum of maximum amplitude versus frequency. The software constantly compares the measured values for each parameter with the user-defined specifications, and real-time results are displayed in a small window. The SC28 can be configured to send an email to the user if any parameters shift beyond the allowed margins. This can be done either once or at a specified frequency, making sure that the issue is dealt with in a timely manner. In addition, a traffic light beacon can be used to give a visual warning, something that can be useful in a manufacturing environment such as semiconductor production.

02 Nov, 2021

The SC11 Analysis System is for making surveys and the SC28 Monitoring System is for long term monitoring of the environment of electron microscopes and related tools. They use some of the same sensors, but for different purposes. The SC11 has higher performance, flexibility and automation for making surveys and troubleshooting at different sites. Our new SC28 is designed for continuous long term monitoring. It is suitable to be placed in one location and let it continuously log timestamped charts and spectra while also alerting you when the environment is out of specification. This provides electron microscope operators with complete peace of mind for the long-term stability of their instrumentation. Click here to see more comparisons between SC11 and SC28.

05 Oct, 2021

A crucial element of establishing a stable environmental is a rigorous site survey prior to installation by either an independent service provider or the equipment supplier, to determine the presence of any disruptive external factors that may have adverse effects on image quality. Typically, this will include measurement of acoustic levels, magnetic fields and floor vibrations in X, Y and Z directions, and direct comparison with the environmental specifications of the equipment to be installed. Where necessary, action can then be taken to eliminate any unwanted interferences, such as installing a magnetic field cancelling system. Site surveys With more and more equipment being squeezed into laboratories, bench space is increasingly more valuable. Electron microscopists face the challenge of working in a crowded environment surrounded by other apparatus that depends on electricity to function, which potentially impacts on image quality. Site surveys have a vital role to play when investing in microscopy instrumentation, and can help to troubleshoot and resolve issues that may arise at a later date, especially as cities and towns grow and become more urbanised, increasing the potential for interference. In addition, in the drive to continually improve resolution and image quality, manufacturers’ environmental specifications are becoming ever more stringent, with top end microscopes with spectrometers only able to withstand up to 10 or 20 nanotesla of interference; finding an environment that is as suitable as possible can be extremely challenging. Mitigating interference In many cases, microscopes are installed into an existing facility, either to complement the equipment currently in use or as part of a new laboratory set-up. In this situation, there is generally little that can be done about the prevailing infrastructure and space constraints, and it is often a case of choosing an installation site as far removed from potential interferences as possible and installing a magnetic field cancelling system. New purpose built laboratories provide the opportunity to design an environment optimised to microscope performance; all the interested parties can communicate from the outset to incorporate the optimal infrastructure and choose the ideal location, as far removed as possible from internal and external influences. For example, air conditioning units can be installed in a separate plant room away from the laboratory, electrical power cables routed to minimise any potential interference, and consideration given to appropriate siting of other equipment to reduce any likely effects on the microscopy instrumentation. Even the location of the car park in comparison to the microscopy room can be considered! How can interferences be eliminated? Where relocation is not possible, additional measures can be taken to combat the severity of vibrations and magnetic fields. Concrete blocks are a popular choice for isolating the microscope system from the rest of the building. This reduces the vibrations from building sway that transmit through the floor and into the structures of the microscope, causing them to resonate at different frequencies. Another option is active vibration isolation, which uses a platform of transducers to move the system in the opposite way and is able to respond fast enough to ensure that any phase lag is minimal. Top-end microscopes can only withstand minimal interference, so finding a suitable environment for the equipment can be extremely challenging. It is becoming increasingly common for electron microscope users to seek advice from experts to mitigate unwanted interferences, with one solution being to install a magnetic field cancelling system. Spicer’s proprietary field cancelling technology has been developed over many years, and there are now thousands of these systems in use worldwide. To find out more about Spicer’s comprehensive pre-installation site surveys and magnetic field cancelling systems, contact us here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

05 Oct, 2021

New technologies are continually being developed, leading laboratories to introduce more machinery and electronic equipment into their workflows and making space within these labs more precious than ever. A busy indoor setting, combined with the growth of noisy and bustling cities outside, causes significant disruption to electron microscopy due to interference from vibrations and external magnetic fields. Therefore, electron microscopy relies heavily on maintaining a stable environment, so areas should be surveyed meticulously before set-up to ensure that the image quality produced will be unaffected by these external factors. What causes interference? The performance of an electron microscope is affected not only by interference within the room in which it is positioned, but also by the location of the building itself. There are several possible sources of interference, but the most commonly encountered problems will arise as a result of vibrations through the floor or the air – acoustic vibrations – or from magnetic fields. Vibrations can come from any apparatus that has the ability to move or rattle – whether intentionally or not – including other machinery, doors opening and closing, air flow from an open window, the engine of a vehicle or laboratory personnel simply moving around. Similarly, magnetic fields can arise from multiple sources, both within the building and externally. The major source of this kind of interference is from power lines in the walls, with magnetic fields across the world normally occurring at two main frequencies – 50 and 60 hertz. Internal interferences also include magnetic fields generated by other equipment, lights (particularly fluorescent tubes) or nearby lifts. It is important to remember that external factors may also be involved, such as vehicles including trains and the electric trams that are growing in popularity in many urban areas. Magnetic fields generated from these can extend for hundreds of metres, unknowingly affecting electron microscope image quality, unless a site survey is conducted to uncover any problems and take suitable preventative measures. Variations in temperature can also interfere with the instrument’s imaging capabilities by causing specimen drift in the microscope electronics and changes in the mechanical tolerances of components. For more information on how Spicer can help you optimise your EM, contact us to find out here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

By spicerconsulting

•

14 Aug, 2020

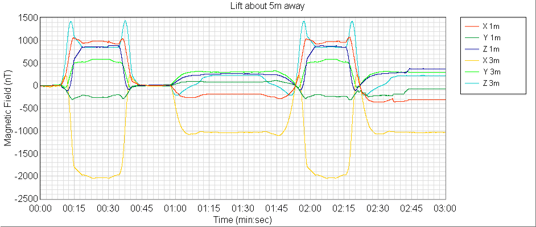

Following on from our first article on the subject, here are some other examples showing site survey data and the resulting improvements in microscopy performance that can be achieved after identifying the cause of the interference and taking appropriate action. Underground train systems Both vibrations and magnetic fields should be measured when studying the effects of an underground system. As the frequency of public transport systems increases due to demand, so does the level of interference. Cancelling systems are frequently needed to overcome the effects of the world becoming busier. Lifts It is often tricky to determine how close you are to a lift. It might seem as if you’ve walked along a few corridors to get to a microscopy room, but, in fact, you may have simply looped round in a square, bringing you back within metres of a lift. As lifts move up and down floors, they trigger interference gradients that constantly change over different heights, causing images to wander and jump around the screen due to large changes in magnetic fields. The interference is often so apparent that it is even possible for site survey readings to pinpoint which floor a lift is on. Lifts provide essential accessibility and ease of movement around facilities, so they are often unavoidable. In these instances, a cancelling system is the only solution. Vehicles The movement of vehicles in close proximity to microscopy rooms can create varied levels of interference, with larger magnetic field peaks coming from heavier vehicles, such as lorries or buses. A magnetic field cancelling system is often required to overcome these disturbances, as it is increasingly difficult to find areas that are not in the immediate vicinity to busy roads. Magnets Although it may seem obvious that magnets have magnetic fields, large systems built around magnets – such as NMR platforms – are designed to keep as much field inside as possible, and therefore the extent of their effect should, in theory, be minimal. In reality, it is unknown without conducting a site survey. In the situation even at a distance of 25 metres the field is multiple orders of magnitude above what can be tolerated by an electron microscope, and it is advisable to move the instrument and magnet further apart. Miscellaneous sources Site surveys commonly uncover unexpected causes of interference. There was significant interference from an unknown source, and a survey was able to locate the source of interference as coming from a hearing loop that had been left behind ceiling tiles. In this case, the problem was easily rectified by renovation work. Conclusions As the world becomes a busier place and more technology is incorporated into laboratories, there are undoubtedly challenges in setting up and maintaining a stable microscopy environment, but measures can be put in place to ensure these are mitigated. The key is to think ahead and engage in discussions with microscopy suppliers, site surveyors and, in the case of a new build, architects, at the earliest possible opportunity. Having an experienced site surveyor with the right equipment is vital to identify common and unusual causes of interference and understand the magnitude of their effects. They can then advise on the best way to counteract these problems. This will allow electron microscopy to be installed in the most stable environment possible, whether it is in an existing facility or a newly set-up laboratory, ensuring the highest quality imaging is maintained. For further information on Spicer site survey services and cancelling systems, contact us here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

By spicerconsulting

•

26 May, 2020

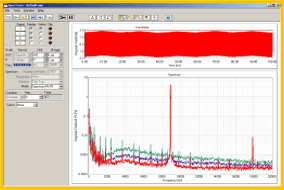

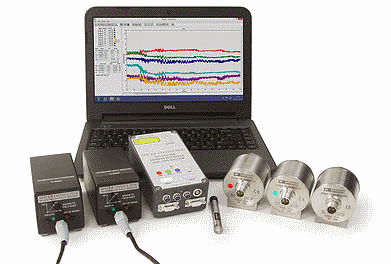

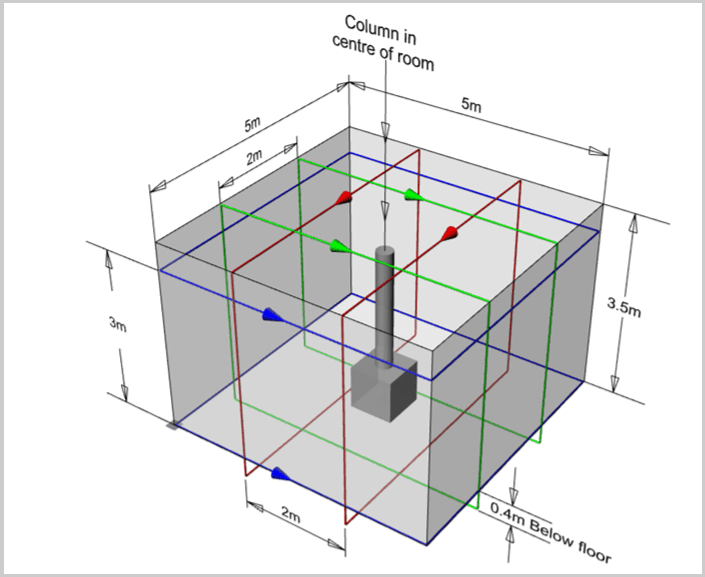

The importance of a suitable environment for the best electron microscope performance is well known. As technology has advanced over the years, microscopes have become more sensitive to interference, which can originate from all manner of causes, including vibrations and magnetic fields from nearby equipment, doors opening and closing, traffic, power cables, trains and lifts, as well as problems in the power supply, such as badly wired fluorescent lighting and ground loops. This is why Spicer Consulting developed the SC11 Analysis System in 1996, purpose designed to perform site surveys, so that you know whether the environment is in spec for the instrument that you require. Nowadays, the SC11 is the gold standard for screening environments where a new microscope might be installed, or for troubleshooting technical issues with an existing microscope by measuring and analysing any interference. In both scenarios, a site survey measures magnetic fields and floor vibrations in X, Y and Z directions, as well as acoustic levels, directly comparing these values with the environmental specifications of the equipment to be installed. Any problems can be identified from this analysis, and solutions proposed, such as the installation of a magnetic field cancelling system. But how has the system adapted to the needs of our customers over the last 20 years? The hardware The SC11/Basic was developed in response to the need for a system that could measure the entire environment of a microscope. Although systems existed before this, they often included poor magnetic field sensors, and so the SC11/Basic was based on one of Spicer’s AC magnetic field sensors, but with added inputs for an accelerometer and a sound level meter. This system could make all the measurements required, but the user had to physically turn the vibration sensor in each direction to measure interference in the x, y and z axes! From there, the system was upgraded so that more bandwidth of data could be collected, and higher frequencies could be evaluated on the spectrum analyser. Further rounds of upgrades, including a move to USB connection, led to the development of the SC11 sensor interface – SC11/SI – which allowed the SC11 to perform better measurements with more sensors. Then, a plug-in for DC sensors was added – so that AC and DC fields could be measured – along with three accelerometer inputs, allowing measurement in all three directions at the same time, instead of having to turn the sensor around. While the original only had only one magnetic field sensor input, later versions had two, enabling the simultaneous measurement of fields at two heights. This feature was important for TEM environments, which typically have tight field specifications over a length of more than two metres. What about software? The SC11 software has developed in parallel to changes in the hardware, and we are now on version 5.6.4. On first release, three separate programs were required – an oscilloscope, a chart recorder and a spectrum analyser – to make the necessary measurements, but the user needed a good understanding to be able to set them up correctly. To address this, we created the Wizard, which was able to guide the user through the process of measuring for different types of microscope. This was perfect for individuals who didn’t use the SC11 very often; they were able to simply turn the machine on, select the instrument they wanted to measure for, and the Wizard would bring up the correct program to make that specific measurement. We also created our own graph plotting software SC Plot, which allowed results to be viewed more easily than the original method using Excel macros. While the Wizard software was capable of running a single measurement, the next development, the Survey automation program, was capable of running a whole sequence of measurements to simplify the workflow for users even more. Today’s SC11 Today, the SC11 is the most comprehensive purpose-designed surveying tool, standing the test of time over the last 20 years and used by leading electron microscope manufacturers worldwide. The SC11/Auto is now a completely automated system, capable of repeat surveying without human intervention. This enables long-term measurements, useful for expanding the surveying snapshot to study the environment at different times of the day. So, if you are planning the installation of your next electron microscope or experiencing technical issues with your existing system, see how the SC11 could help by visiting https://www.spicerconsulting.com/which-sc11-you .

By spicerconsulting

•

26 May, 2020

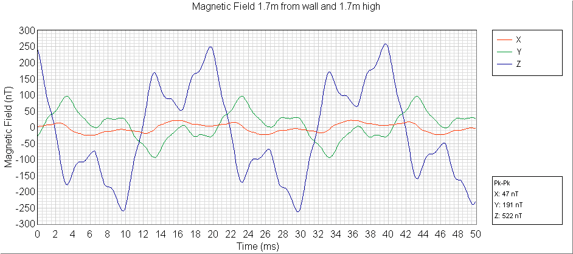

It is important to measure both vibration and magnetic field interference at different locations and heights when conducting a site survey, to see how signals change amplitude in all three axes. This helps to locate the cause of any problems, so that it is easier to implement measures to reduce or eliminate interference. It can be as simple as relocating the microscope, taking out the cause of the interference, or installing a cancelling system to improve microscopy performance as demonstrated in the following examples. Power cables Power cables run through many areas of a building and can be a common cause of interference for electron microscopes. The live wire in a power cable carries electric current to an appliance, while the neutral cable completes the circuit, to form a path for the current to flow back to the mains. These two wires should effectively cancel each other out but, as the currents in the wires get larger, the current difference between the wires grows and this leads to large magnetic fields. Distribution boards Distribution boards are essentially central hubs that distribute power around various circuits in a building or lab. They are a source of large magnetic fields, and every effort should be taken to place an electron microscope as far away as possible because, even at a small distance away. The interference levels are much higher than the tolerance level of the microscope. Earth leakage current In some instances, site surveys can actually uncover problems in the power supply. Large leaks down the earth wire produce huge magnetic fields, which can often be identified by turning off different areas of power supply. Lighting Typically, lights are turned off in microscopy rooms during imaging, but occasionally lighting can still cause interference. In general, LEDs tend to be the best to use for electron microscopy labs, whereas fluorescent lights should be avoided. Changing the lights is often the simplest solution to overcoming the problem. Trains and Trams Trains produce interference that is far greater than the levels than can be tolerated by electron microscopes, depending on how far away the tracks are. The rate of train runtime can also determine the amount of disruption as regular activity – not only from vibrations as trains pass by, but also from magnetic fields running along the power lines – can affect instruments hundreds of metres away. Similarly, trams can also produce vibrations and magnetic fields that can be disruptive. The tram line itself is set on a hill and this influences the level of interference, based on whether a tram is going up or down the slope. However, in this situation, a microscope was still installed but with the addition of a magnetic field cancelling system to disrupt the impacts of interference. For further information on site survey services and magnetic field cancelling systems, contact us here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Magnetic Field Cancelling Systems Articles

By spicerconsulting

•

04 Mar, 2020

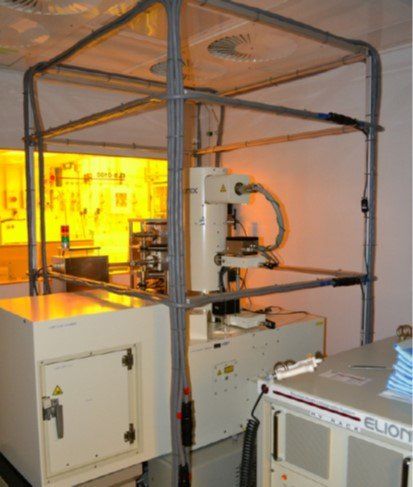

The production of semiconductor components on a nanometre scale has become more practical than ever, thanks to advancements in manufacturing. Electron microscopy – such as TEM, SEM and FIB-SEM – is an important quality control tool in the manufacture of these semiconductors, allowing structural analysis of devices to detect any problems. However, the image quality of these instruments is commonly affected by interference from surrounding magnetic fields, making it more challenging to identify manufacturing errors. The benefits of smaller components The semiconductor industry is under constant pressure to make components smaller. The desire to continually increase computing speed and power – while saving costs – means that more transistors are needed within each chip. However, placing additional transistors on a chip produces more heat. One way to keep the transistors cooler is to make them smaller, as the distance that the electrons have to move to do the same job is smaller, and therefore takes less energy. This also makes the whole system faster, which is more economical, as there is more functionality built into the same space on a silicon wafer. External factors can limit resolution Despite the advantages of creating smaller components, miniaturisation poses a challenge during manufacture, as a higher level of magnification is needed to inspect the parts. Electron microscopy is often used to perform due to the high resolution that this technique provides. When imaging features on a chip with an electron microscope, the electron beam must be positioned with a level of accuracy that is similar to the size of feature being examined to achieve required resolution. Unfortunately, electron microscopes are particularly sensitive to magnetic fields, which can deflect the electron beam. The smaller the object, and therefore higher the necessary resolution, the more sensitive the technique is to the surrounding magnetic fields – as well as vibrations and sound. The manufacturing environment will often experience a lot of magnetic field interference, as the most problematic frequency – around 60 Hz – is produced by an abundance of different machinery. As the space within most manufacturing sites is valuable, this leads to as many instruments as possible being packed into a given area, and this close proximity results in microscopy interference. In addition, newer semiconductor factories often feature ceiling-level monorail systems to transport components between stations for automatic loading and processing, which also helps with traceability of materials. These overhead systems typically create a 9 kHz magnetic field, which is incredibly detrimental to image quality and must be cancelled in order to improve resolution. Other contributing sources of magnetic field interference within semiconductor factories include magnetic stirrers used in plasma etchers and voice-coil actuated stages in lithography machines. Finding the most stable environment In the semiconductor industry, manufacturers often have highly-sensitive electron microscopes working alongside large pieces of industrial equipment – which produce various types of radiation – so it’s important to find a way to allow them both to work in harmony. This level of sensitivity requires areas to be surveyed meticulously before microscope installation, to ensure that the image quality produced will be unaffected by any external factors. Instruments such as Spicer Consulting’s purpose-designed SC11 Analysis System are routinely used by microscope vendors and consultants to perform site surveys for SEMs, TEMs and similar equipment. These instruments measure and analyse magnetic fields, vibrations and acoustics in X, Y and Z directions, displaying results graphically and allowing the user to perform a direct comparison between the fields encountered and the microscope specifications. This information is invaluable to ensure that electron microscopes are installed in the most stable environment possible – whether that is in an existing facility or a new laboratory – ensuring the highest possible image quality. Improving image resolution Top-end microscopes can only withstand minimal interference, so finding a suitable environment for the equipment can be extremely challenging. It is becoming increasingly common for electron microscope users to seek expert advice to find solutions to mitigate unwanted interferences, such as installing a magnetic field cancelling system. Spicer’s proprietary field cancelling technology has been developed over many years, and there are now thousands of these systems in use worldwide. All Spicer cancelling systems – including the popular SC24 – consist of a Magnetic Field Control Unit and one or more Magnetic Field Sensors, as well as three multicore cables, which are installed around the electron microscope. There are two different types of sensors that can be used depending on the interference present; the first only measures AC fields, whereas the other more complicated and high performance sensor can detect both high frequency AC and low frequency fields down to DC. The control unit includes power amplifiers that drive currents through the cables when interference is present, creating a nearly equal and opposite field. This dynamic response – which automatically compensates for field changes within 100 μs – stabilises the ambient field, restoring resolution. Conclusion There are many technical challenges involved in miniaturisation of semiconductor components, and both surveying instruments and cancelling equipment are essential in supporting the advancements within this industry. With a broad install base around the world, Spicer Consulting’s solutions have proven to be highly effective in restoring resolution in electron microscopes in manufacturing environments. For more information on how Spicer can help you optimise your EM, contact us to find out here . About Spicer Consulting Limited Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools. Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Site Survey and Monitoring Articles

05 May, 2023

The unparalleled magnification capabilities of electron microscopes (EMs) make them indispensable for applications requiring nanometre scale imaging. However, the sensitivity required to operate at such high magnification levels leaves them vulnerable to magnetic field perturbations, vibration and changes in temperature and humidity, all of which need to be kept to a minimum to ensure peak performance. Keeping track of such environmental factors is no mean feat, but dedicated continuous monitoring systems are now available to detect changes in instrument surroundings in real time, simplifying troubleshooting procedures and ensuring optimal device performance. Blurred lines The superior magnification offered by EMs stems from the use of electrons instead of light to probe a sample; the wavelength of these particles can be many orders of magnitude shorter than photons on the visible spectrum, enabling them to resolve much smaller features. The beam of electrons is focused on the specimen, and interacts with atoms in the sample to produce signals that contain information about surface topography and composition. Seeing details at such a small scale requires the beam to be perfectly positioned and focused, which can be compromised by external interferences from acoustic noise and vibrations, leading to blurred images. Additionally, since the electrons are charged particles, EM performance is also greatly affected by external magnetic fields. This leads to distinct artefacts appearing in the image; AC fields often show up as sharp jagged edges, while DC fields create wavy lines. EM manufacturers therefore precisely map and specify the degree of interference that their instruments can handle before the image quality drops below the acceptable limit.

05 May, 2023

Electron microscopes (EMs) are vital quality control (QC) tools in semiconductor production, helping manufacturers to guarantee a high standard of product. However, the precision of EMs and the resolution of resulting images can be hindered by external interruptions, such as acoustic noises, vibrations and magnetic fields. Low resolution and perturbed images can make it hard to detect faults in semiconductor products, which could in turn decrease the yield and performance of manufactured goods. Therefore, continually assessing the quality of the imaging environment and pinpointing any potential sources of disturbances is critical to maintaining a high standard of production. Fortunately, there are dedicated systems on the market designed especially for continuous monitoring of the environment surrounding sensitive EMs, which now provide uninterrupted and automatic logging of various environmental parameters to revolutionise electron beam (EB) instrument applications. Failure analysis is an important component of QC in semiconductor production, which can ultimately help to enhance yield and guarantee a high standard of manufacturing excellence. However, smaller and smaller semiconductor devices are being developed, making it increasingly difficult to perform failure analysis and locate defects in products. Various high-resolution EM tools – including scanning electron microscopy (SEM), focused ion beam scanning electron microscopy (FIB-SEM) and transmission electron microscopy (TEM) – are helping to analyse the structure of even the smallest devices. This is crucial for localising and characterising defects and electrical problems that may affect performance, solidifying these EM instruments as cornerstones of the QC process. Unfortunately, the environment in which the EM is located can have a significant impact on image quality, as external factors – such as acoustic noises, vibrations, and magnetic fields – lower the resolution and make it harder to find defects. In addition, these disturbances can also cause instability or shifts in the EB, resulting in significant reductions in resolution, so that instruments perform below their intended design specifications. It is therefore important to the quality of imaging that these types of disturbances are identified when the instrument is first installed within a semiconductor manufacturing or research environment. They must also be continually monitored throughout their use, as subsequent or transient changes to conditions can cause ongoing problems for operators. Surveying the environment Surveillance of the environment prior to installation should be a standard when investing in any EB instrument, in order to ensure that the microscope or lithography machine is placed in an appropriate location that will enable it to operate to its desired specifications. There are purpose-made survey systems for this application – such as Spicer Consulting's SC11 family – which are able to measure both vibrations and external magnetic fields. Once installed, many EB instrument users also perform long-term surveillance of the environment to help identify any drifts in continuous fields or transient disruptions that could impact performance. However, until recently, the technologies available for this ongoing environmental monitoring have been missing one critical feature – the ability to measure several parameters simultaneously without any interruptions in data collection. Continuous feedback An innovative monitoring system (SC28 Monitoring System, Spicer Consulting) that continuously logs magnetic fields and floor vibration in three axes, as well as acoustic levels, temperature and humidity, has recently launched onto the market. This system can be controlled via a computer connected to the same local area network, and all the gathered information is automatically stored in date-stamped files by the software. This program can also be used to define environmental specifications, either as minimum/maximum values, or as a spectrum of maximum amplitude versus frequency. The software constantly compares the measured values for each parameter with the user-defined specifications, and real-time results are displayed in a small window. The SC28 can be configured to send an email to the user if any parameters shift beyond the allowed margins. This can be done either once or at a specified frequency, making sure that the issue is dealt with in a timely manner. In addition, a traffic light beacon can be used to give a visual warning, something that can be useful in a manufacturing environment such as semiconductor production.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Subscribe to our product information and email newsletter

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.