Which Magnetic Field Cancelling System is for you?

Spicer Consulting magnetic field cancelling systems are purpose-designed to reduce the magnetic field in the environment of electron microscopes and similar sensitive equipment. Thousands of our systems are in use worldwide, protecting instruments from all the major electron microscope, electron beam lithography, CD metrology and focussed ion beam manufacturers.

Today’s high performance electron beam tools are very sensitive to changing ambient magnetic fields. These fields are often referred to as electomagnetic interference or EMI. The fields move the beam causing loss of resolution and image distortion. Spicer Consulting cancelling systems reduce the ambient magnetic field and restore the resolution and image quality of the microscope. This process is sometimes called EMI cancellation.

All our cancelling systems comprise a Magnetic Field Control Unit, one or more Magnetic Field Sensors and three multicore cables, which are installed around the microscope for which the field is to be cancelled. Three power amplifiers in the control unit drive currents through the cables to create a field of the opposite sign to the change in ambient field. The magnetic field sensor measures the resulting field and real time negative feedback reduces the ambient field by the loop gain of the system. It is a cost-effective method which can be added to or replace passive magnetic field shielding.

All Spicer Consulting cancelling systems share the following features.

- Makes the ambient magnetic field “OK” for the electron microscope

- Full 3-axis (X, Y, Z) system

- Option to mix dual sensors to create a virtual sensor “inside” the EM column. This feature is useful for large TEMs or where there is a high field gradient.

- Different systems cancel different frequency ranges. All systems cancel 50/60 Hz AC line fields.

- Automatic setup

- Colour LCD display

- Field display of X, Y, Z and Total field with choice of Tesla or Gauss units

- "Field Ok" indication on control unit and sensors

- Trip indicators show which axis went above the preset level

- All cancelling systems are Nemko certified.

The following comparison highlights the differences between the available models

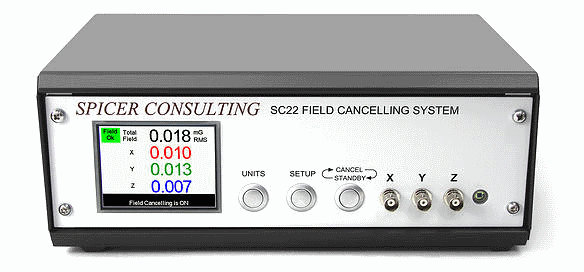

SC22 Magnetic Field Cancelling System

- Lower cost

- Cancels and displays AC fields only

- Simple 3-button user interface

- Option for dual sensors using external mixer

- USB port for remote operation and monitoring

- Room size or frame mounted cable options

- 50 x field reduction at 50/60 Hz

- Bandwidth 2.5 Hz to 5 kHz

- Adapts to field changes within 100 μs

SC24 Magnetic Field Cancelling System

- Higher performance

- Cancels and displays AC and DC fields

- Touch screen user interface

- Built in mixer for dual sensors

- Automatic DC reset

- Adjustable trip levels

- Built-in test field generator

- USB and Ethernet ports for remote operation and monitoring

- Room size or frame mounted cable options

- > 50 x field reduction at 50/60 Hz

- > 400 x field reduction at DC with DC sensor

- Bandwidth 2.5 Hz to 5 kHz with AC sensor

- Bandwidth DC to 5 kHz with DC sensor

- Adapts to field changes within 100 μs

SC26 Magnetic Field Cancelling System

- Purpose designed to protect electron beam tools in the vicinity of overhead wafer transport robots in 300 mm semiconductor wafer fabs

- Cancels 50/60 Hz and 9kHz magnetic fields

- Also cancels DC fields with added DC sensor

- Displays AC and DC fields

- Touch screen user interface

- Built in mixer for dual sensors

- Automatic DC reset

- Adjustable trip levels

- Built-in test field generator

- USB and Ethernet ports for remote operation and monitoring

- Cables are fitted inside the cabinet of the tool

- 20 x field reduction at 9 kHz

- 40 x field reduction at 50/60 Hz with AC sensor

- 200 x field reduction at DC and 50/60 Hz with added DC sensor

- Adapts to field changes within 10 μs

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Contact Us

We will get back to you as soon as possible.

Please try again later.