Blog Post

How site survey technology has evolved in the pursuit of perfecting electron microscope performance

spicerconsulting • Apr 23, 2021

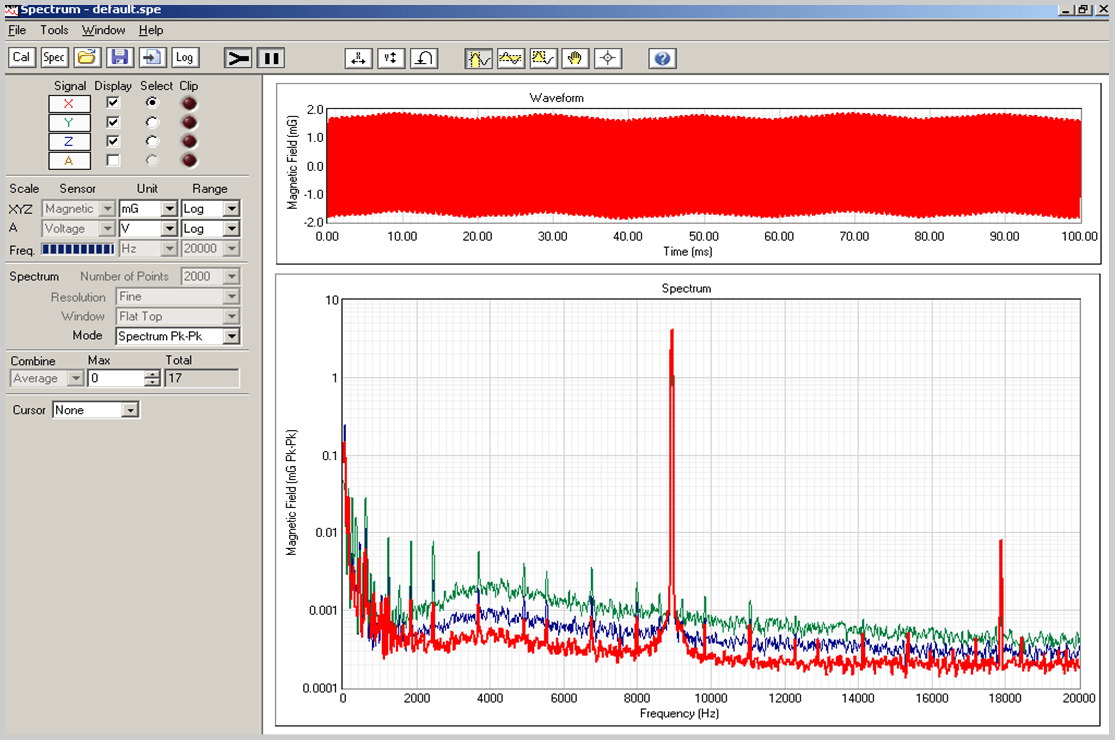

Spectrum Analysis– In-depth Analysis of Magnetic Field, Vibration, Acoustics

External magnetic fields and vibrations can often impact the performance of an electron microscope, reducing the image quality and resolution. Pre-installation site surveys are vital for uncovering any potential sources of interference, and are the first step to creating a stable environment, but require purpose-designed equipment for the measurement and analysis of acoustics, and magnetic fields and vibrations in X, Y and Z directions. This article discusses the importance of comprehensive site surveys for identifying and mitigating potential sources of interference of electron microscopes (EMs) and similar sensitive equipment, and describes how one company has addressed this through the continual evolution of its measurement instrumentation.

Hidden interference

Electron microscopes are powerful yet sensitive tools, and are commonly used to investigate the intricate structures of cells, materials and nanoparticles for many technical disciplines, such as metallurgy, chemistry and biology. All electron microscopy techniques – including the two most common, transmission electron microscopy (TEM) and scanning electron microscopy (SEM) – use a beam of accelerated electrons as a source of illumination for the sample. Electrons have a shorter wavelength than visible light protons, which allows electron microscopes to have a significantly higher resolving power than light microscopy, revealing the detailed composition of smaller specimens. However, day-to-day equipment can cause interference through acoustics, vibrations or magnetic fields, causing this electron beam to deflect, which decreases the resolution and quality of the images obtained.

Eliminating interference

Ongoing technological advancements mean laboratories continue to expand and invest in an increasing amount of electronic equipment, so making space within these labs is more challenging than ever. Electron microscopists often find themselves working in a crowded environment, surrounded by other apparatus that creates magnetic fields, vibrations or acoustic interference, which potentially adversely affect image quality. This busy setting, combined with the growth – and noise – of towns and cities, causes a significant problem for electron microscopy. In addition, in the drive to continually improve resolution and image quality, manufacturers’ environmental specifications are becoming increasingly stringent, with top end microscope spectrometers only able to withstand up to 10 or 20 nanotesla of interference; unsurprisingly, finding a suitable environment can be extremely challenging.

Investigations of microscopy instrument performance often begin with a crucial site survey. This can help to troubleshoot and resolve issues that may develop at a later date, or as a result of environmental changes that introduce sources of interference. The performance of the instrument is affected not only by conditions within the room in which it is installed, but also by the location of the building itself. Anything that moves or rattles – whether regular or random – can potentially create vibrations, including other electronic equipment, air conditioning systems, people simply walking around the laboratory, doors opening and closing, traffic in the street, nearby railways and even ocean waves. External factors, such as magnetic fields generated by trains and electric trams that are hundreds of metres away, and unexpected influences like the proximity of the car park to the microscope, can make a tremendous difference.

Surveying the site before set-up allows measures to be put in place to ensure that interference is mitigated and the environment is stable enough for microscopy. Typically, this will include measurement of acoustic levels, magnetic fields and floor vibrations in X, Y and Z directions, and direct comparison with the environmental specifications of the equipment to be installed. Measuring and understanding the magnitude of such effects will enable action to be taken to alleviate unwanted interferences, for example, by installing a magnetic field cancelling system, to ensure that the image quality produced is unaffected by external factors.

Keeping up with technology

As technology has advanced over the years, microscopes have become more sensitive to interference, and sensing equipment has had to keep pace to ensure that the environment meets the manufacturer’s specifications for optimal instrument performance. Today, purpose-designed site survey equipment is available for vendors and consultants to examine new installations effectively, or to measure and analyse interference with an existing microscope to troubleshoot any technical issues. But how has this progressed over the years?

Advances in hardware

In the early days of EM, labs relied on some quite crude magnetic field sensors to monitor the environment, with limited options for measuring fluctuations in noise levels. There was a clear need for a single system that could monitor the entire lab situation around a microscope and, in 1996, Spicer Consulting launched an instrument based on an AC magnetic field sensor, with added inputs for an accelerometer and a sound level meter, that would do just that. This system could make all the measurements required, although the user still had to physically turn the vibration sensor in each direction to measure interference in the X, Y and Z axes.

The system was later upgraded to collect a greater bandwidth of data, and evaluate higher frequencies on the spectrum analyser. Further upgrades, including a move to USB connection, enabled site surveyors to perform more comprehensive measurements with extra sensors. A plug-in for DC sensors was added – so that AC and DC fields could be measured – along with three accelerometer inputs, allowing measurement in all three directions at the same time, instead of having to turn the sensor around sequentially. While the original instrument only had one magnetic field sensor input, later versions had two, enabling the simultaneous measurement of fields at two heights. This feature was important for TEM environments, which typically have tight field specifications over a length of more than two metres.

Advances in software

Naturally, the software of newer systems also had to be updated along with the hardware. On first release, three separate programs were required – an oscilloscope, a chart recorder and a spectrum analyser – to make the necessary measurements, but the user needed a good understanding to be able to set them up correctly. This was made far easier by the creation of a software wizard to guide the user through the process of measuring for different types of microscope. Users were able to simply turn the machine on, select the instrument they wanted to measure for, and the wizard would bring up the correct program to make that specific measurement. Graph plotting software was also developed, which allowed results to be viewed more easily than with the original method, which was based on Microsoft Excel® macros. While the wizard software was capable of running a single measurement, further iterations saw the launch of an automation program capable of running a whole sequence of measurements to simplify the survey workflow even more. Today, users have access to a completely automated system capable of repeat surveying without human intervention. This enables long-term measurements, expanding the surveying snapshot to study the environment at different times of the day.

Finding a pragmatic solution

Implementing a magnetic field cancellation system can eliminate any magnetic field interference that is identified during a site survey. This presents further challenges, requiring a three-axis magnetic field sensor of the necessary bandwidth with low noise levels and low drift. It should include a control unit that can drive the cables to form a stable negative feedback loop, and be easy to set up without complex adjustments. Finally, effective placement of room sized cancelling cables that make uniform orthogonal magnetic fields and are practical for use in microscope labs or clean rooms of all shapes and sizes must be determined. Alternatively, suitable frames can be constructed to support cables and there are also techniques for installing them inside existing enclosures.

Spicer Consulting supplies control units that provide readings in three axes, plus total magnetic field readings – including AC and DC simultaneously for some models – with performance tailored to the application. These are convenient to use and enable fields to be cancelled to the demanding levels required by today’s high-resolution electron microscopes. Automatic set-up can provide helpful error and warning messages, and some cancelling systems support a dual-sensor option that creates a virtual sensor where a physical sensor cannot be placed, such as ‘inside’ the EM column. A wide range of cables for different types of microscope in various types of room are also available.

The future of magnetic field cancellation

Technology for mitigating magnetic fields is continually developing to match increasing demand as the ever-improving resolution of electron microscopes makes them more sensitive to magnetic fields. While the technology is already quite advanced, it is expected that users will seek even better magnetic field sensors, incremental improvements to control units and easier ways to install cancelling cables in the future. Contact us here

for site survey service or a site survey kit.

About Spicer Consulting Limited

Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools.

Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Subscribe to our product information and email newsletter

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.