Anticipating magnetic field interference issues prior to installation

Electron microscopes offer unparalleled image resolution and are widely used in research laboratories to investigate the structure of various biological and inorganic structures. These powerful tools are, however, susceptible to interference from magnetic and acoustic fields, which decrease the image quality. ZEISS, an internationally renowned optical expert, is therefore using sophisticated surveying equipment to inspect sites prior to system installation.

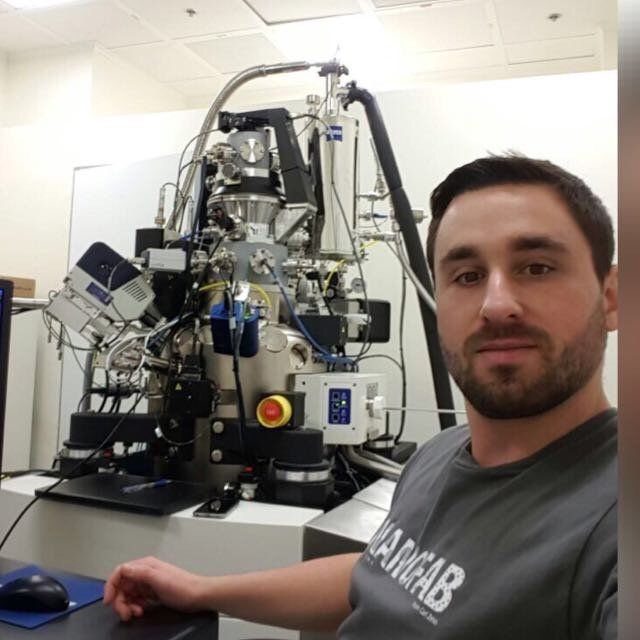

ZEISS is one of the world’s leading manufacturers of optical systems and provides a wide range of services and products used for semiconductor production, research and quality technologies, medical devices and vision care. An example of this is the use of the company’s high resolution scanning electron microscopes (SEMs) for surface topology imaging in life sciences and materials research. The installation of such high tech equipment requires careful planning to ensure that they perform as well as the customers expect them to. Christian Hegele, International Service and Support Engineer at ZEISS, explained: “It is very important that the site is adequately surveyed before setting up an electron microscope; you need to ensure that the room is big enough, and check for interference that could decrease the image quality. Since electronic and acoustic interference, as well as floor vibrations, can have a huge impact on the performance of electron microscopes it is crucial to detect any problems that may arise in order to provide a solution.”

Dedicated equipment to scan for interference

ZEISS has been using the SC11 Sensor Interface Analysis System from Spicer Consulting since 2008, allowing the company to survey the environment and check if laboratories are suitable prior to installation. Christian continued: “The system is very user-friendly and the results are displayed graphically on connected laptop screens, allowing us to reliably assess the area. We have created templates specifying the requirements of each of our microscopes, which can simply be run on the SC11 system using the Spicer Wizard software; everything is automated, making it extremely easy to use, even for less experienced service engineers. The templates are available online and can be accessed by our staff around the world, and since the majority of our service engineers are now using Spicer equipment, it means that we can ensure consistently high quality results. It’s an excellent way to standardise the service that we provide, and allows us to have confidence that each survey will be performed with accuracy and reliability, and to ensure that our staff is familiar with the benefits of the systems.”

Long collaboration with Spicer

Spicer was recommended to Christian by one of his colleagues, a former service engineer who had years of experience with its magnetic field cancelling systems. Christian continued: “I went on a two-day course organised by the company before I started performing the surveys, where I learned more about the system as well as how to train our own engineers. This was a really interesting experience, and the products were fantastic. We are now working on establishing an in-house training programme for new engineers, or those switching over to the Spicer systems. On top of that, we also use Spicer’s purpose-designed SC22 Magnetic Field Cancelling Systems, which can reduce stray magnetic fields – both AC and DC – and also handles vibrations. The SC22 increases the resolution and accuracy of our SEMs and, when surveying our customers’ sites, we often recommend this tool to enhance the performance of our systems, as it is incredibly effective at removing interference.”

“We work extremely closely with Spicer in order to deliver the best possible service to our customers. Both the SC11 and SC22 are intuitive and easy-to-use, and if we ever encountered any problems or simply wanted to make changes to the systems, our enquiries were quickly and efficiently addressed. We have an excellent relationship with the team after years of using their products, and are incredibly impressed with what they do. We work very well together and are looking forward to continuing our collaboration with Spicer in the future,” Christian concluded.

Contact Spicer Consulting Ltd for our SC11 site survey kit or magnetic field cancelling system here.

About Spicer Consulting

Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focussed ion beam tools.

Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers.Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Contact Us

We will get back to you as soon as possible.

Please try again later.