SC11 helps Hitachi High-Technologies to optimise performance of their electron microscopes

Electron microscopes are sensitive to magnetic and acoustic fields in the environment, and determining the cause of, and tackling, interference is vital to ensuring optimal performance. Global company Hitachi High-Technologies is using sophisticated surveying and cancelling systems to overcome the challenges faced when installing and maintaining this equipment.

Hitachi High-Technologies is an international corporation that offers a wide range of cutting-edge products and services in four areas: science and medical systems; electronic device systems; industrial systems; and advanced industrial products. As part of its scientific systems, the company manufactures a variety of electron microscopes suited to all applications, as Carl Hordines, Southeast District Service Manager in the US, explained: “Hitachi offers a range of scanning and transmission electron microscopes which range in size from desktop to more than 10 feet tall taking up multiple rooms. Installation of these complex instruments is not always straightforward; they can be affected by electromagnetic interference (EMI) – caused by factors from transformers to elevators and metal doors – acoustic interference – from things like heating, ventilating and air conditioning (HVAC) systems – and even vibration – traffic, nearby building works or even someone just walking down a corridor.”

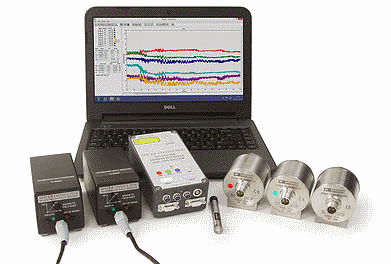

“As part of the installation process, we survey the site using the SC11 Analysis System from Spicer to identify anything that might affect the microscope’s performance and recommend any preventative measures – such as field cancellation systems or vibration isolation tables – that might be required. For example, I recently surveyed a site where a large crane was in use and it was evident at the outset that this was going to cause interference with the microscope being installed. I was able to use the SC11 to measure the DC field while the crane was moving, and this confirmed what I had anticipated. This type of information helps us to advise the customer, perhaps suggesting where an instrument might be better placed in relation to external factors, as well as powerlines, and water and gas sources.”

Carl continued: “We had already used a Spicer magnetic field cancellation system to prevent interference on a number of projects, when we saw a demonstration of the SC11 Auto Survey System. It was evident from this that our survey equipment needed upgrading and we decided to purchase several for our installation teams. The SC11 is purpose-designed for surveying sites for electron microscopes and other sensitive equipment, and offers a higher quality microphone and more sophisticated sensors than our previous system. We no longer have to move the sensor numerous times to gather multiple readings, and the report generation is much quicker. I can use the macros to run a survey that gives us a really good snapshot of a location in around 25 minutes.”

“The SC11 also increases the efficiency of data collection because the whole process is integrated into the system – it’s all automated. The software is compatible with Microsoft® Office so it’s easy to pull up data without the need to copy and paste between different programs. I have an Excel® spreadsheet for each model of microscope we offer, that will read raw data and populate the tables against the specifications for that particular instrument. This allows me to determine which models will work best in a specific space or facility, without the need for multiple site visits.”

“For studies that are more complex, we can leave the system in place for extended periods of time. It is straightforward to schedule multiple runs or to start recording data when an interference hits a set level or, when the need arises, we ship a kit to a customer site if they unexpectedly encounter a problem. The system is very robust and comes with a durable shipping case, and it’s so easy to use that anybody can set it up with minimal instruction – even with no prior experience.”

“The SC11 systems are now solely responsible for all of our internal and external surveying, which ensures continuity throughout our work, and we’re so happy with them that we have recently added two more to the four we already own; they are so efficient, we wouldn’t be without them,” concluded Carl.

For more information on how Spicer can help you optimise your EM, contact us to find out

here

.

About Spicer Consulting Limited

Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools.

Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Contact Us

We will get back to you as soon as possible.

Please try again later.