Blog Post

Identifying and overcoming the source of magnetic field interference

Oct 07, 2021

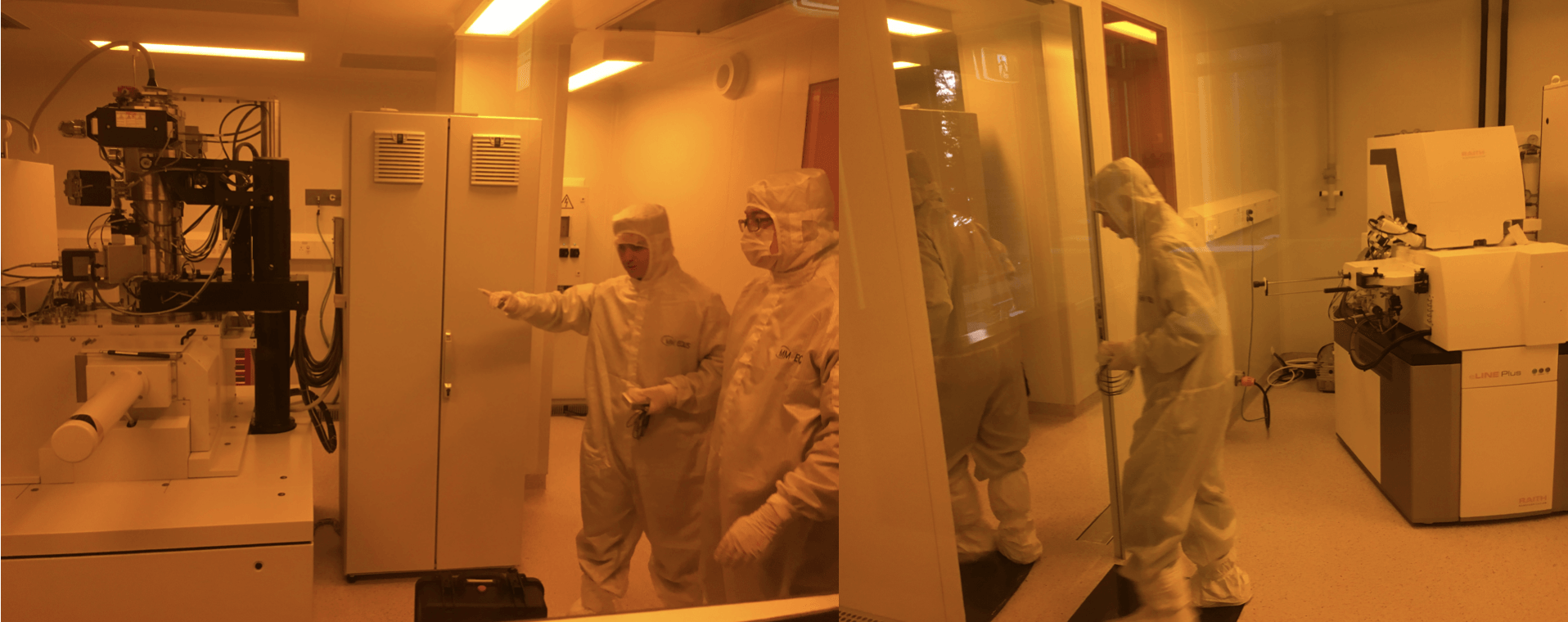

The University of Queensland Case Study

Electron beam lithography is commonly used to fabricate small devices used in computers, photonics and sensors. Since the technology relies on accurate positioning of the electron beam, it is very sensitive to interferences like vibrations and stray electromagnetic fields. Elliot Cheng, Electron Beam Lithography (EBL) Specialist, and Roger Wepf, Director of the Centre for Microscopy and Microanalysis (CMM) at The University of Queensland, describe how they solved this problem using a Spicer SC24 magnetic field cancelling system.

CMM is an electron microscopy facility involved in research and teaching, as well as providing consultancy services. The centre offers expertise in different electron microscopy technologies and has recently built a new clean room where computer, photonics and sensor devices are fabricated using EBL. However, the new facility immediately began to present real challenges to the researchers when they started seeing unexplained background noise showing up in their data. Elliot explained: ”The devices we’re making are extremely small and it is crucial that the electron beam is accurately positioned, something that is greatly affected by any magnetic interferences. Ideally, levels on this kind of application should not be higher than 0.5 milligauss, but we were seeing peaks located around 50 Hz that were significantly higher than that, which jeopardised the accuracy of the instrument.”

“We used the Spicer SC11 analysis system to scan for factors that might cause this interference around the lab, and it was extremely convenient to have a portable sensing system that allowed us to chase down the sources of noise without having to call in an external contractor. We started by investigating the vibrations, which we quickly realised were not causing the problem and moved on to checking the AC magnetic fields, looking at the contributions from various frequencies. When that proved fruitless, we analysed the DC fields and found that this was the root of the issue. This led us on a ‘ghost hunt’; we walked around with the SC11, turning different instruments on and off, moving the elevators, all while constantly measuring the changes in the field. After a while, we could attribute some of the spikes to the elevators, which was not surprising, but another source remained unknown. It was periodic, with a one-minute cycle and eventually we figured out that it was caused by the inductive heating of the lab.”

“We had the answer but it didn’t really help us solve the issue. We couldn’t remove this source of interference, and started to schedule our runs during hours when no one else was in the building, which was between 11pm and 4am. Some of the processes were automated and we could get around this by programming them in advance, but this really limited the usability of the instrument. We therefore decided to purchase the Spicer SC24 magnetic field cancelling system, and immediately noticed a great improvement in the noise reduction – going from around 2 to just a few tenths of a milligauss – and we no longer have to worry about moving elevators or the nearby traffic. We still need to optimise the location of the sensors to get the best performance out of them, but the instrument is already doing a great job now that the problem of interference has been mostly eradicated.”

Roger continued: “I have worked with Spicer for a long time; I started using their products around 1996 and have always used its instruments to perform an environmental survey every time we have installed a new instrument. I believe that it is absolutely essential to have a Spicer analysis system in every EM lab, because it saves a lot of time, and gives the team the freedom to perform on-site measurements as soon as they are needed, or if changes to the environment occur.”

About Spicer Consulting Limited

Since it was established in 1988, Spicer Consulting has built a world-wide reputation in magnetic field cancelling for Electron Microscopes and similar instruments. Today, working with equipment manufacturers and users alike, the company is recognised as an industry expert in maximising the performance of electron microscopes, electron beam lithography systems, CD metrology and focused ion beam tools.

Spicer Consulting magnetic field cancelling systems protect sensitive equipment in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for the conduct of site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s Golden Triangle of elite universities in London, Cambridge and Oxford.

Resonate Systems

is Spicer Consulting Limited’s distributor in Australasia. They provide technical and sales support for Spicer’s products. Visit www.resonatesystems.com.au

for more details.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Subscribe to our product information and email newsletter

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.